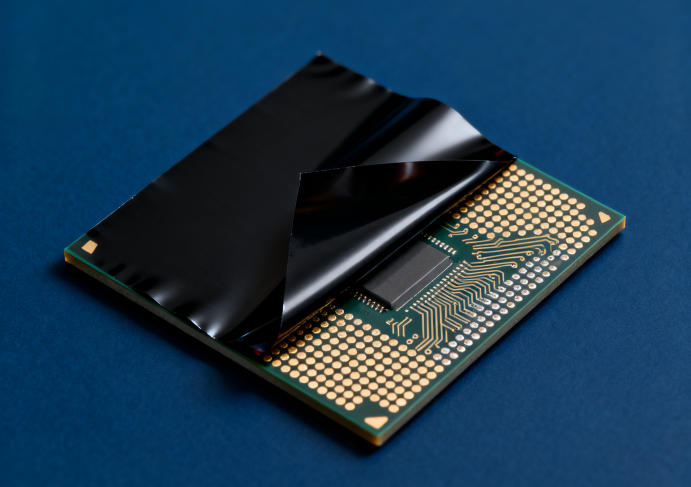

In recent years, the pace of product iteration in the communications industry has accelerated continuously. Flexible displays, with their unique advantage of enabling screen folding and unfolding, significantly reduce device footprint and have thus gained significant market favor. When traditional yellow transparent polyimide film is used as a cover layer, printed circuit designs are highly susceptible to being deciphered and replicated. Moreover, in high-end fields such as aerospace, to ensure the stable operation of imaging systems, sensors, and other sensitive components, it is essential to shield them from stray light interference. Typically, these components are housed within light-shielding fixtures. Consequently, many technicians have begun exploring the use of black polyimide film to fabricate such fixtures.

There are three primary methods for preparing black polyimide films. The first is the in-situ dyeing method, which involves adding black pigment or dye particles as additives to the polyimide solution, followed by a film-forming process to produce the target film. The second is the composite method, where black resin is coated onto a polyimide film and cured at elevated temperatures to obtain a black film. The third is the intrinsic method, which involves molecular design to introduce chromophores into PI molecular segments. This promotes charge transfer (CT) within and between PI molecules, resulting in significant absorption in the visible light spectrum.

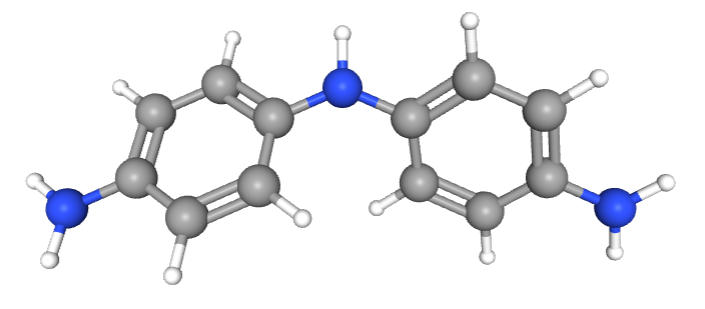

A common approach involves incorporating the aromatic diamine monomer 4,4'-diaminodiphenylamine (NDA), which contains imine-based chromophores, into the PI formulation. On one hand, the lone pair electrons on the imine N atom in the NDA molecular structure promote CT; while the imine group (-NH-) undergoes high-temperature oxidation during PI film preparation, directly forming black material.

However, the structures of these polyimides often contain large conjugated systems or numerous chromophores. This results in limited solubility of the resulting polyimides after polymerization, frequently necessitating the use of high-boiling-point solvents such as N,N'-dimethylacetamide as reaction solvents. Additionally, some researchers have attempted to improve solubility by coupling alkyl chains to the main structure. However, this approach typically compromises mechanical properties, creating a difficult trade-off between solubility and mechanical performance. Furthermore, the inherent black color of these polymer systems makes it difficult to detect defects such as foreign particles or bubbles during polymerization and coating processes, complicating quality control.

Consequently, developing inherently black polyimide films that maintain excellent electrical properties while offering good optical shielding and mechanical performance presents a significant challenge.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.