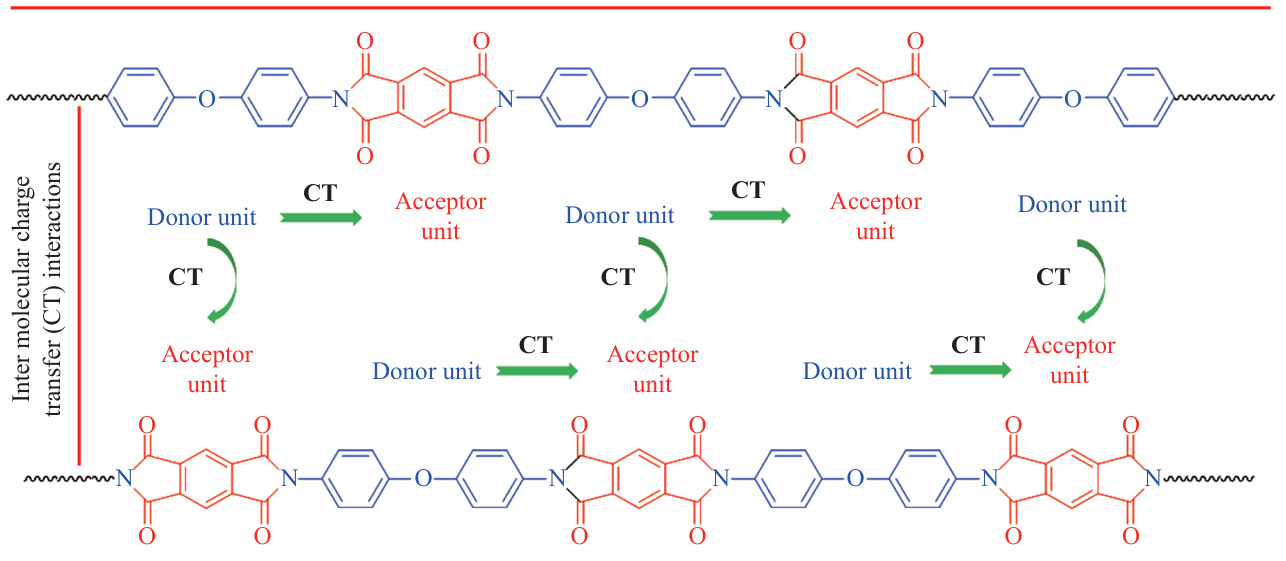

Traditional polyimide (PI) films are typically brown or amber-colored transparent materials. This is due to the presence of strong electron donors (diaminodiphenyl ether, ODA) and electron acceptors (p-benzenetetracarboxylic dianhydride, PMDA) within the PI molecular structure. These components form strong charge-transfer complexes (CTC) within or between PI molecular chains, causing the chains to pack tightly. This results in significant absorption of visible light and low transmittance. To achieve colorless, transparent polyimide, monomer regulation must occur prior to synthesis to disrupt conjugated interactions within the molecular chain, eliminating charge transfer phenomena at the molecular level. However, structurally reducing CTC generation to obtain favorable optical properties often comes at the cost of altering other material characteristics.

The electronegativity of fluorine atoms (3.98) is the highest among all elements, and their small atomic radius (0.071 nm) effectively reduces the polarity and polarizability of molecular chains. Simultaneously, the steric hindrance of fluorine atoms diminishes the close packing between molecular chains, forming a “low-polarity, low-density” molecular structure that ultimately endows the film with ultra-low dielectric properties. Currently, researchers are introducing fluorinated groups into the polyimide backbone to suppress CTC formation, thereby enhancing the light transmittance of polyimide films and reducing their yellow index.

As the electronic materials field continues to advance, the challenges of fluorinated polyimide materials have become increasingly apparent. Their core raw materials (such as hexafluorobenzene-1,2,3,4,5,6-dicarboxylic anhydride (6FDA) and fluorinated diamines) rely on specialized fluorochemical synthesis processes, which are difficult to produce, yield low output, and cost 3–5 times more than non-fluorinated raw materials. Furthermore, fluorinated monomers exhibit low reactivity, requiring higher temperatures and extended durations for polycondensation. Incomplete imidization often occurs due to steric hindrance from fluorine atoms, further escalating production costs. Although fluorinated polyimides exhibit low dielectric constants, the polarity of fluorine atoms leads to elevated dielectric loss tangents (tanδ often exceeds 0.005 in high-frequency bands like 5G millimeter waves). This causes signal attenuation during transmission, failing to meet the core requirement of “low loss” for high-frequency communications. During high-temperature processing or disposal, fluorinated transparent polyimides may release trace fluorinated gases (e.g., HF), which corrode production equipment and violate global carbon neutrality and environmental policies.

In today's technological wave, material innovation has become the key to continuous breakthroughs across all industries. Particularly in high-end electronics, aerospace, optoelectronic displays, and other fields, material performance often dictates the direction of technological advancement. As a more environmentally friendly, sustainable, and high-performance technological material, non-fluorinated colorless polyimide (NF-CPI) is gradually emerging as the “new favorite” in modern high-end materials. Through molecular structure optimization, NF-CPI films achieve outstanding optical properties including high visible light transmittance and low UV yellowing. Inheriting the heat resistance of the polyimide family while avoiding the molecular chain instability caused by fluorine atoms, it demonstrates exceptional thermal endurance. Its balanced intermolecular forces (π-π conjugation + van der Waals forces) strike a balance between flexibility and strength, delivering high flexibility, superior bend resistance, and high mechanical strength. The absence of fluorine atoms ensures environmental friendliness and strong process compatibility, fundamentally avoiding the environmental and process challenges associated with fluorinated materials. The protection of acrylamide rings and stable chemical bonds (C-C, C-N) within its molecular chains confers exceptional chemical and weather resistance.

The development of fluorine-free transparent polyimide films is driven by the combined forces of optoelectronics industry demand, material performance adaptation, green manufacturing trends, and cost-effectiveness. It overcomes the “visual limitations” of traditional opaque polyimides while circumventing the “cost and environmental drawbacks” of fluorinated transparent polyimides. Ultimately, it delivers unique value—combining high performance, high adaptability, and environmental sustainability—in fields such as flexible optoelectronics, high-end displays, and new energy. This positions it as a critical material underpinning the advancement of next-generation flexible electronics technology.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.