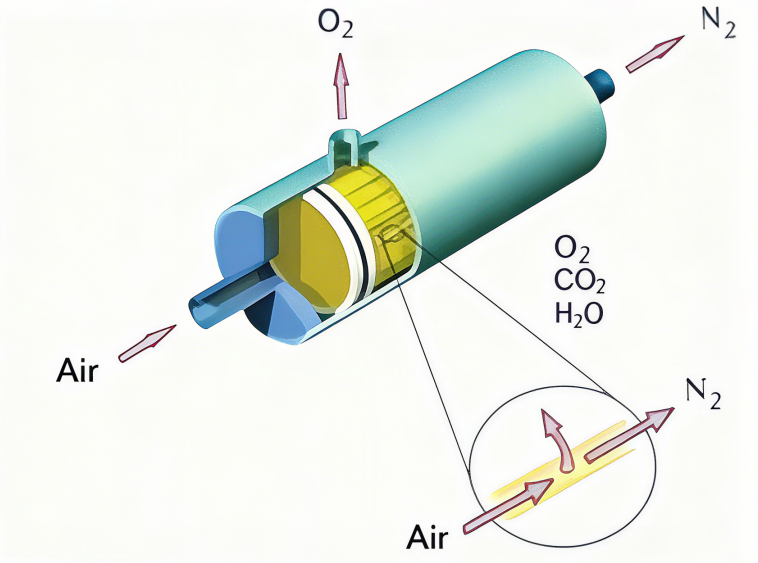

Gas separation membrane technology leverages the differences in permeation rates of various gas molecules through membrane materials to achieve separation, representing an emerging“green technology”. Compared to traditional gas separation techniques such as cryogenic deep cooling and pressure swing adsorption, membrane separation offers advantages including high efficiency, energy savings, flexible operation, simple and compact equipment, and environmental friendliness. It enables highly selective gas separation at ambient temperatures, thereby attracting widespread attention in both fundamental research and industrial applications. Since the 1980s, membrane separation processes have been applied across diverse gas separation fields, including: - Separating N2 from air - Separating CO2 from natural gas - Separating C2~C4 hydrocarbons in petrochemical plants - Extracting H2 in refineries and ammonia plants. In recent years, other emerging applications have developed, such as separating CO2/H2 mixtures, separating CO2/N2 for carbon capture, enriching oxygen/nitrogen in air, and separating olefins/paraffins.

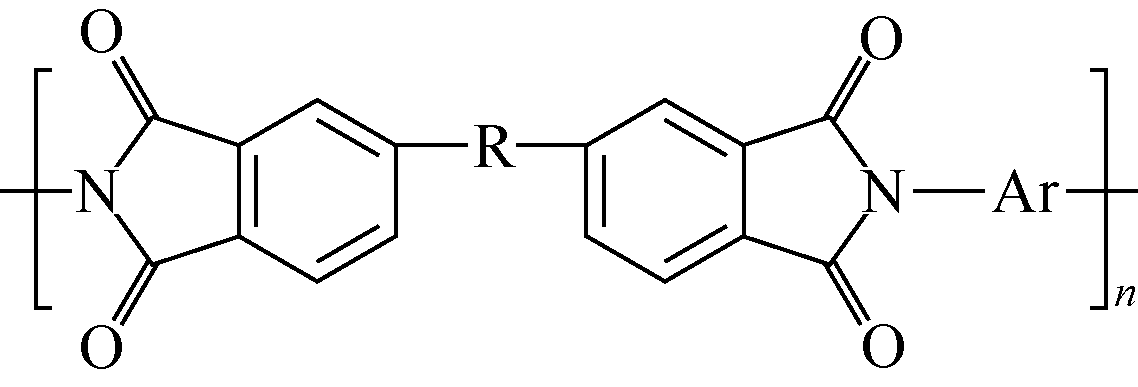

Polyimides (PIs), as high-performance polymers, have the following general structural formula and are typically synthesized by polycondensation of a dianhydride and a diamine. Aromatic polyimides are a class of polymers featuring imide rings in their main chains. Based on the type of imide ring, they can be further categorized into five-membered ring polyimides and six-membered ring polyimides. Currently, the vast majority of polyimide membranes used for gas separation are five-membered ring polyimides. Polyimides exhibit characteristics such as flexibility, excellent film-forming properties, and ease of modification and functionalization. They also possess high-temperature resistance, thermal stability, solvent resistance, chemical stability, and good mechanical properties. These attributes make them one of the ideal materials for high-performance gas separation membranes. However, the number of polyimide materials formally deployed in industrial applications remains limited. This is because all membrane materials often exhibit a trade-off between permeability and selectivity, meaning high permeability is typically accompanied by low selectivity, and vice versa. Consequently, developing membrane materials that combine high permeability with high selectivity is a current research priority. Simultaneously, membrane materials face significant durability challenges during long-term operation. The primary cause of reduced membrane permeability is the aging of polyimide materials, which has become a critical challenge limiting both the upper performance limit and service life of the membranes. Consequently, in-depth investigation into the physical aging phenomena of polyimide materials holds practical significance for guiding their application in gas separation membranes.

Currently, researchers have conducted laboratory-scale development and gas separation performance evaluations on numerous polyimide structures. By adjusting the material's chemical structure or physical form, they seek the optimal balance between the core trade-off of “permeability” and “selectivity” while addressing practical challenges such as resistance to plasticization and solvent resistance. This has led to the exploration of multiple modification strategies:

1. Chemical Structure Modification: This fundamental approach directly regulates gas transport channel dimensions and interactions by altering the polyimide molecular chain structure. Introducing specific groups or functional groups into the dianhydride or diamine enables enhanced preferential adsorption and permeation of target gases (e.g., CO2) through group-gas interactions, thereby improving gas selectivity. Alternatively, copolymerizing two or more dianhydride/diamine monomers combines the advantages of different monomers, achieving performance trade-offs to meet specific separation requirements.

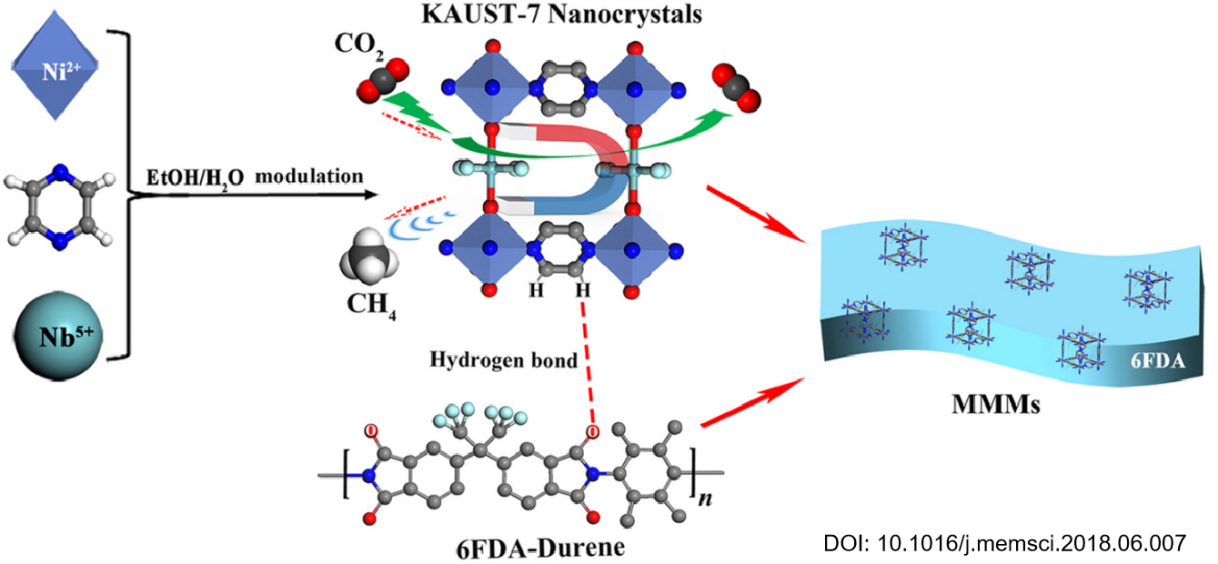

2. Physical Morphology Modification: Without altering the main molecular chain structure, this approach optimizes gas transport pathways by adjusting the macroscopic or microscopic morphology of the membrane. Preparing hybrid matrix membranes by dispersing inorganic fillers (e.g., molecular sieves, MOFs, graphene) into the polyimide matrix. The porous structure of inorganic fillers provides additional gas transport pathways while leveraging their sieving effects to enhance selectivity, achieving a synergistic “1+1>2” effect.

3. Surface Modification: Treating the membrane surface through strategies such as plasma etching and surface coating to optimize gas-surface interactions, repair surface defects, and enhance gas selectivity and fouling resistance.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.