Aerogel is a typical nanoporous material formed by the aggregation of colloidal particles or polymers, serving as a highly dispersed three-dimensional porous solid with gas as its dispersion medium. It was first synthesized in 1931 by Samuel Stephens Kistler at the University of the Pacific in California, USA, using supercritical drying technology. Owing to its ultra-high porosity, aerogel exhibits properties such as low refractive index, low thermal conductivity, low dielectric constant, low acoustic impedance, high specific surface area, and ultra-low density. It holds broad application prospects in thermal insulation, adsorption catalysis, energy storage and drug delivery, seismic resistance and pressure reduction, sound insulation and absorption, ion capture, and aerospace applications. Based on chemical composition, aerogels can be categorized into organic aerogels, inorganic aerogels, and composite aerogels. Traditional inorganic aerogels exhibit fragile mechanical properties and are prone to damage. For instance, the three-dimensional porous framework of silica aerogel consists of loosely connected nanoparticles, resulting in poor structural stability. Additionally, conventional inorganic aerogels demonstrate inferior chemical and environmental stability, with performance degradation occurring during prolonged use. They are sensitive to corrosive media such as strong acids and alkalis, leading to framework corrosion and decomposition, rendering them unsuitable for long-term operation in harsh chemical environments. Compared to traditional inorganic aerogels, organic polymer aerogels exhibit superior mechanical properties and environmental stability. Since the first polymer aerogel was synthesized in the 1980s, organic polymer aerogels have undergone extensive development.

Polyimide (PI) is regarded as a high-temperature engineering polymer with broad application prospects due to its favorable mechanical properties, excellent chemical resistance, good dielectric performance, and high-temperature stability. Polyimide aerogel (PIA) is a three-dimensional porous material formed by cross-linked polymer chains. It combines the outstanding properties of both polyimide and aerogel, inheriting not only the excellent characteristics of polyimide but also many distinctive features of aerogel. Thus, polyimide aerogel materials have rapidly emerged as one of the most promising organic aerogels. The outstanding performance characteristics of polyimide aerogel are manifested in the following aspects:

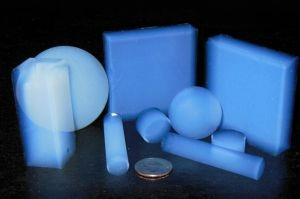

Ultra-low density: Inheriting the lightweight properties of aerogels, it serves as an ideal lightweight material with significant application value in fields with strict weight constraints.

High specific surface area and porosity: Typically exhibiting high porosity exceeding 90%, with specific surface areas reaching hundreds of square meters per gram, endowing it with excellent adsorption and barrier properties.

Excellent thermal properties: Exhibits high glass transition temperature (Tg) and thermal decomposition temperature (Td), such as certain polyimide aerogels with Td 5%>580oC and Tg>299oC. Combined with low thermal conductivity, it delivers outstanding high-temperature insulation performance.

Excellent mechanical properties: The molecular chain rigidity of polyimide confers high mechanical strength. Polyimide aerogel retains this characteristic to a significant degree, enabling it to withstand external forces without deformation or damage.

Superior chemical resistance and dielectric properties: Polyimide itself exhibits outstanding chemical resistance and excellent dielectric properties. Polyimide aerogel inherits these characteristics, maintaining stability in harsh chemical environments.

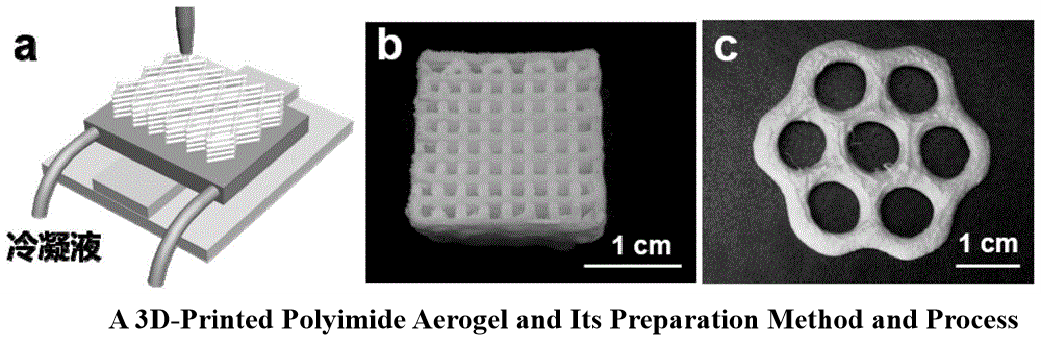

Polyimide aerogels, leveraging their unique combination of high-temperature resistance, lightweight properties, low thermal conductivity, and high mechanical strength, find core applications in fields demanding extreme material performance, such as aerospace, high-end industrial equipment, electronic devices, environmental protection, and catalysis. Despite its numerous outstanding properties, polyimide aerogel prepared via the sol-gel method using commercial dianhydride and diamine monomers suffers from high shrinkage rates and poor dimensional stability. This makes it difficult to simultaneously achieve low density and low thermal conductivity, hindering its broader practical application. Nevertheless, researchers continue to explore novel preparation methods and monomer structures to address these challenges. For instance, developing new diamine monomers and copolymerizing them with dianhydride monomers enables the creation of polyimide aerogel materials with moderate rigidity and superior dimensional stability.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.