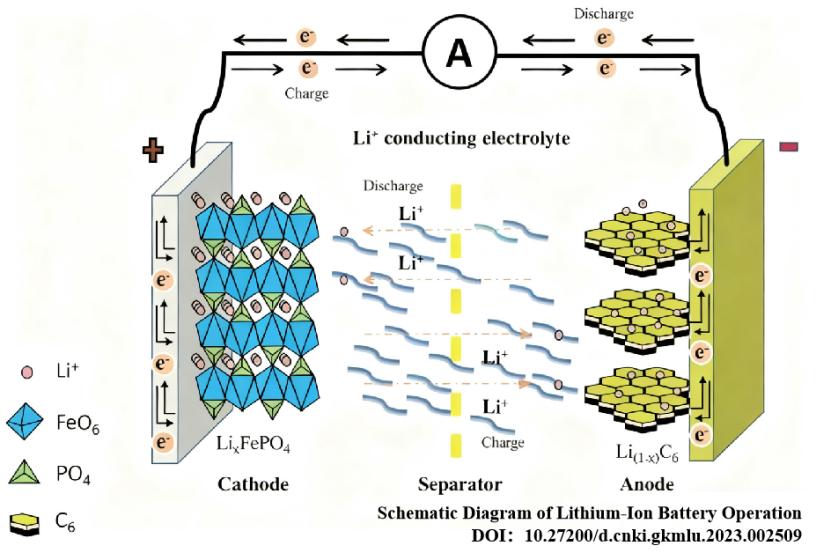

With the rapid advancement of electric vehicles and electronic devices, developing energy storage devices featuring high energy density, enhanced safety, and accelerated charging speeds has become an urgent necessity. Lithium-ion batteries (LIBs) are rechargeable batteries that store and release energy through the insertion and extraction of lithium ions between the cathode and anode. Due to their high energy density, long cycle life, absence of memory effect, and environmental friendliness, LIBs have emerged as the core technological approach for new energy storage and conversion. Lithium batteries primarily consist of four key materials: cathode material, anode material, electrolyte, and separator. The lithium battery separator is one of the core components, with its performance critically influencing battery safety, energy density, and cycle life. Serving as an insulating layer, the separator isolates the battery's positive and negative electrodes, preventing direct contact that could cause short circuits and ensuring battery safety. Its nanoscale microporous structure provides pathways for lithium ions to migrate between electrodes, enabling normal charging and discharging. Furthermore, during abnormal temperature spikes, the separator's microporous structure automatically closes or the separator melts, blocking ion transport to prevent thermal runaway and providing critical safety protection.

Lithium battery separators primarily consist of three types: polyolefin separators, composite separators, and novel separators. Traditional polyolefin separators, including polyethylene (PE), polypropylene (PP), and their composite films, are currently the most widely used lithium battery separator materials, accounting for over 90% of the market. Composite separators enhance performance by coating the polyolefin base film with functional materials like ceramics or aramid fibers, or by employing multi-layer composite structures (e.g., PE−PP, PP−PE−PP). However, the inherent poor wettability and thermal stability of polyolefin materials make it difficult to meet the mass transfer requirements for high-rate rapid charging. Additionally, the poor thermal stability can cause thermal shrinkage deformation of the separator, leading to overheating and short circuits at high rates, and potentially causing battery explosions. In recent years, researchers have been dedicated to developing alternative lithium battery separator materials with excellent thermal stability.

Polyimide separators (PI separators) for lithium batteries represent a novel battery separator material with outstanding properties. They exhibit exceptional thermal stability, maintaining structural integrity above 500°C, with long-term operating temperatures reaching 200-300°C. This capability effectively blocks the propagation of thermal runaway triggered by high temperatures within the battery, significantly enhancing battery safety. PI separators also exhibit self-extinguishing properties, with a limiting oxygen index (LOI) as high as 35-37%, far exceeding traditional polyolefin separators (approximately 18%). This significantly reduces the risk of battery combustion. The polar groups within the PI molecules strongly adsorb the electrolyte, markedly improving wettability. This ensures efficient lithium-ion transport through the separator, enhancing battery charge/discharge efficiency. PI separators also inherit numerous advantages of polyimide materials, such as excellent mechanical strength and insulation properties. They withstand internal stresses and external compression during battery charging/discharging, effectively isolate positive and negative electrodes to prevent short circuits, reduce separator rupture risks, extend battery lifespan, and further enhance overall battery safety. Currently, primary methods for fabricating lithium battery separators include sacrificial template method, non-solvent phase separation (NIPS), electrospinning, and solution jet printing.

With its outstanding performance, polyimide separator is progressively replacing traditional polyolefin separators, emerging as the ideal choice for next-generation high-performance lithium battery separators. In the power battery sector, it significantly enhances the safety, range, and charging speed of electric vehicle batteries, meeting the stringent performance demands of high-end electric vehicles. In the energy storage battery field, it provides more reliable and durable safety assurance for large-scale energy storage power stations, suitable for applications such as grid energy storage and distributed energy storage. Additionally, PI separators meet the demanding requirements of batteries in extreme environments like aerospace and military applications, ensuring stable operation under conditions such as high temperatures, high humidity, and high vibration. Currently, the industrialization of polyimide separators is accelerating, with large-scale commercial application expected within the next few years. This advancement will drive the upgrade of lithium battery technology and enhance overall safety performance.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.