With the advancement of modern science and technology, the environmental impact of electromagnetic radiation continues to grow. Absorbing materials are functional substances that can absorb incident electromagnetic waves and dissipate their energy as heat or other harmless forms. Their core function is to reduce electromagnetic wave reflection and interference, making them widely used in fields such as electromagnetic compatibility and stealth technology. Based on their loss mechanisms—the core principles of absorption—these materials fall into three main categories: dielectric loss-type, magnetic loss-type, and composite loss-type. Their applications have expanded beyond traditional military domains into civilian electronics, addressing diverse scenarios. In military and aerospace, they enable stealth designs for fighter jets, missiles, and satellites, minimizing radar reflection signals. In the electronics sector, they serve as internal absorber linings in phones, computers, and servers, absorbing electromagnetic interference generated by components to ensure stable operation. In daily transportation, they absorb electromagnetic radiation from batteries and electronic control systems in electric vehicles and charging stations, preventing interference with other components. Additionally, they reduce interference between communication signals and onboard equipment in high-speed rail carriages.

One of the core drawbacks of traditional absorptive materials is their poor environmental adaptability. This stems from the insufficient stability of their matrix or absorptive agents, leading to performance degradation in complex environments. For instance, under extreme conditions such as high temperatures, humidity, salt fog, high altitudes, or radiation exposure, the matrix tends to degrade, causing structural damage and a significant short-term decline in absorptive performance. Moreover, traditional materials focus solely on absorptive functionality, failing to address additional requirements such as thermal insulation, flame retardancy, or mechanical reinforcement.

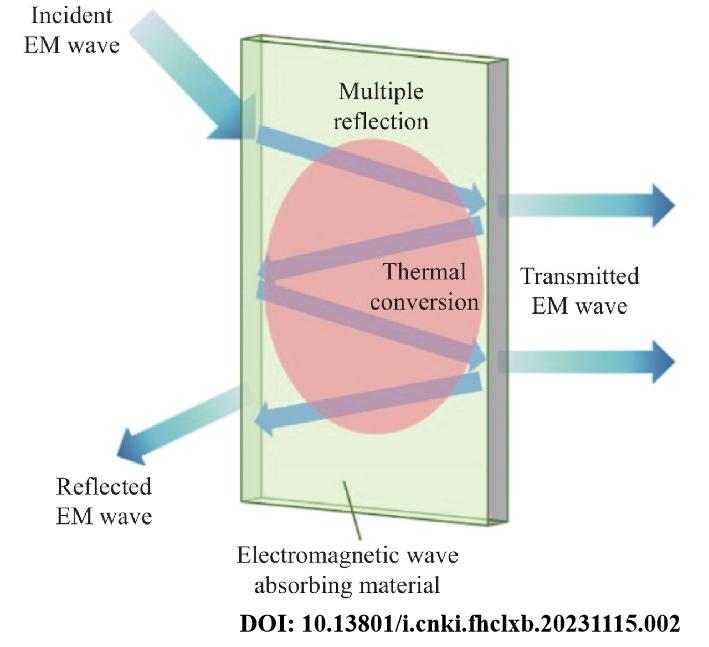

Polyimide absorptive materials are functional composites with a polyimide matrix, exhibiting outstanding electromagnetic wave absorption properties. They find extensive applications in electronics, aerospace, and other fields. Polyimide (PI) is an organic polymer with outstanding comprehensive properties, including resistance to high and low temperatures, radiation, excellent mechanical performance, and good insulation. The absorptive properties of polyimide absorbers primarily rely on their three-dimensional porous structure and added absorbers. The three-dimensional porous structure enables the composite material to achieve appropriate impedance matching, facilitating maximum microwave penetration into the material. Energy is then dissipated through multiple internal reflections and propagation. Absorbers such as carbon nanomaterials possess outstanding dielectric properties, which dissipate incident microwave energy through polarization effects, multiple scattering effects, and inter-particle leakage conductance.

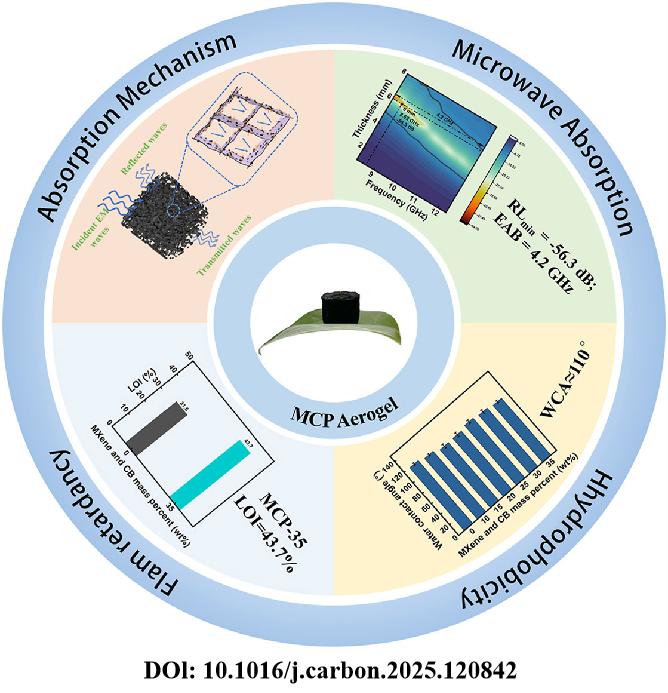

The core factors influencing the absorptive performance of polyimide absorbers can be categorized into three major groups: absorber characteristics, matrix and composite structure, and fabrication process parameters. The absorber serves as the core determinant of the material's absorptive capability, with its type, content, and morphology directly impacting energy dissipation efficiency. Hybrid loss-type absorbers have emerged as a research hotspot in recent years, combining dielectric and magnetic loss mechanisms—such as carbon-metal composites and carbon-ferrite composites. These materials broaden the absorption bandwidth and balance high- and low-frequency performance, representing the current mainstream development direction. Nanoscale absorbers (e.g., nanosheets, nanotubes) possess large specific surface areas and more loss sites. However, uneven dispersion can form agglomerates, leading to internal structural inhomogeneity that impairs uniform electromagnetic wave absorption and transmission. Pure polyimide exhibits low dielectric loss, necessitating chemical modification (e.g., introducing polar groups) to enhance its dielectric properties and assist absorbers in achieving energy dissipation. Controlling the three-dimensional porous structure of the polyimide matrix (e.g., foamed, honeycomb) optimizes impedance matching, allowing more electromagnetic waves to penetrate the material. Simultaneously, multiple reflections within the pores extend propagation paths, increasing opportunities for energy dissipation. Furthermore, different composite methods like solution blending and in-situ growth affect the uniform dispersion of absorbers within the matrix. For instance, in-situ growth enables stronger interfacial bonding between absorbers and the matrix, reducing interfacial reflection and enhancing absorption efficiency. Appropriate post-processing techniques such as annealing and chemical plating can adjust the material's crystal structure and surface conductivity, further optimizing dielectric/magnetic properties and improving absorption performance.

Despite numerous advantages over traditional absorbers, novel polyimide-based absorbers face significant challenges in achieving large-scale production due to drawbacks such as complex fabrication processes and high costs.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.