Photosensitive polyimide (PSPI) is a class of functional polymer materials that combines the excellent thermal stability, mechanical properties, dielectric properties, and photosensitivity of polyimide. It enables patterning processes without relying on additional photoresists, demonstrating unique advantages in microelectronics manufacturing.

The core of PSPI structural design lies in balancing photosensitivity with the intrinsic properties of polyimide, primarily involving two aspects: matrix structure design and the introduction of photosensitive groups. The matrix structure is typically constructed through the polycondensation reaction of aromatic dianhydrides and diamines. By adjusting the types and ratios of dianhydrides and diamines, the material's heat resistance, mechanical properties, and solubility can be controlled. There are two primary methods for introducing photosensitive groups: First, copolymerization, where diamine or dianhydride monomers containing photosensitive groups are copolymerized with conventional monomers, chemically bonding the photosensitive groups to the molecular chain; Second, the doping method involves physically incorporating small-molecule photosensitizers (such as diazonaphthoquinones or azide compounds) into the polyamide acid (PAA) precursor system. The copolymerization method offers greater stability, while the doping method provides more flexible processing options.

Photoresist serves as the core material for pattern transfer in microelectronics manufacturing, requiring high resolution, excellent film-forming properties, etch resistance, and compatibility with substrates. As a photoresist material, PSPI eliminates the need for subsequent stripping processes and offers superior thermal resistance, meeting the demands of high-temperature post-processing in device fabrication. It is primarily applied in the following scenarios:

· Semiconductor Device Insulation Layers: In large-scale integrated circuits, PSPI photoresist can be used to fabricate interlayer insulation films. Its superior dielectric properties effectively reduce signal delay and crosstalk, while its high-temperature resistance withstands subsequent high-temperature processes like metallization. For instance, in multi-layer wiring structures, patterned PSPI insulation layers achieve electrical isolation between different metal layers with sub-micron patterning precision, meeting high-density wiring requirements.

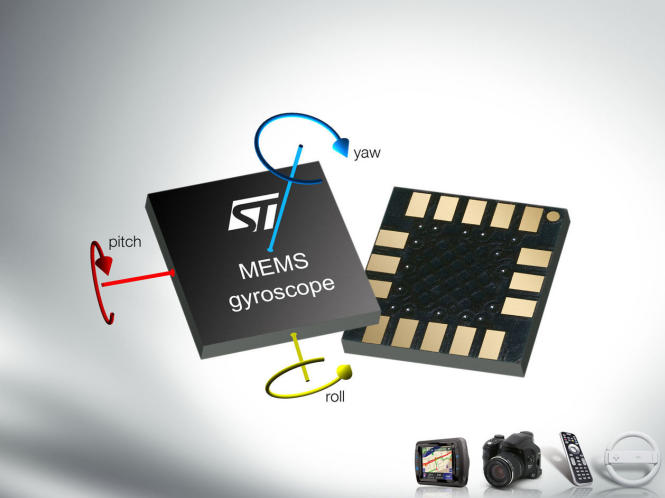

· Micro-Electro-Mechanical Systems (MEMS) Structural Materials: MEMS device fabrication demands high-precision, heat-resistant structural materials. PSPI photoresist can be directly used to fabricate microstructures such as cantilevers, microchannels, and microcavities. Its excellent mechanical properties and chemical stability ensure MEMS device reliability in complex operating environments. Furthermore, PSPI’s patterning process exhibits good compatibility with common MEMS lithography and etching techniques, simplifying device integration workflows.

· Pixel Definition Layer for Display Devices: In OLED, Micro-LED, and other display devices, the pixel definition layer requires high resolution, excellent solvent resistance, and barrier properties. PSPI photoresist enables precise pixel pattern definition. Its low gas permeability and chemical corrosion resistance effectively protect pixel cells, while its outstanding thermal stability withstands high-temperature processing during device encapsulation. Currently, PSPI photoresist for display devices has achieved patterning resolutions below 5 μm and demonstrates potential applications in flexible display fields.

Core requirements for electronic packaging include protecting chips, enabling signal transmission, and facilitating heat dissipation. Packaging materials must possess thermal resistance, moisture resistance, strong adhesion, and excellent dielectric properties. Leveraging its comprehensive performance advantages, PSPI finds increasingly widespread application in electronic packaging, primarily in the following areas:

· Chip underfill material: In flip chip packaging, underfill material fills the gap between the chip and substrate, alleviating thermal and mechanical stresses to enhance device reliability. PSPI, as a underfill material, enables precise filling through photolithography processes. Its excellent thermal resistance withstands high temperatures generated during chip operation, while its low coefficient of thermal expansion minimizes thermal mismatch between the chip and substrate. Furthermore, PSPI’s dielectric properties prevent interference with signal transmission, making it suitable for high-frequency, high-speed chip packaging.

· Packaging Substrate Insulation Layer: As the core carrier in electronic packaging, the insulation layer of packaging substrates must exhibit high thermal resistance, low dielectric loss, and excellent interlayer adhesion. PSPI serves as an insulation layer material for packaging substrates, enabling the definition and fabrication of through-holes via patterning processes. Compared to traditional epoxy and BT resins, PSPI offers superior thermal resistance and long-term stability, meeting the demands of high-density packaging substrates. Currently, PSPI for packaging substrates has achieved ultra-thin applications with interlayer thicknesses below 20 μm and a tanδ value below 0.01, making it suitable for packaging high-frequency communication devices such as 5G components.

· Flexible Packaging Materials: With the rapid advancement of flexible electronics and wearable devices, flexible packaging materials must exhibit flexibility, heat resistance, and excellent processability. PSPI offers inherent flexibility, and its patterning processes adapt to the manufacturing demands of flexible substrates. Currently, flexible PSPI packaging materials are applied in products like flexible OLED devices and flexible sensors. Their bend resistance and environmental stability ensure the reliability of flexible devices during repeated deformation cycles. Additionally, modified PSPI can achieve transparency, meeting the light transmission requirements for flexible display packaging.

Currently, research and application of PSPI still face challenges in high resolution, high sensitivity, moisture resistance, and cost control. Future development trends primarily include: First, precision molecular design, where computer-aided design is used to develop monomer structures with specific properties, enabling precise control over photosensitivity, heat resistance, dielectric properties, and more; Second, functional integration by combining nanotechnology and composite materials to develop PSPI systems with multifunctional properties like high thermal conductivity, high barrier performance, and flame retardancy. Third, greener manufacturing through the development of low-toxicity, low-volatility photosensitizers and solvent systems to reduce environmental impact. Finally, industrial-scale production by optimizing synthesis processes and processing workflows to lower manufacturing costs, thereby promoting the widespread adoption of PSPI in more consumer electronics applications.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.