Carbon Fiber Reinforced Polyimide Composites (CFRP) represent a high-performance composite material. Within this structure, carbon fiber serves as the reinforcing phase, imparting mechanical properties such as high strength and modulus alongside excellent thermal characteristics. Polyimide functions as the matrix, bonding the carbon fibers and transmitting stress. Combining lightweight properties with multifunctional advantages, CFRP demonstrates irreplaceable application value in high-tech fields such as aerospace, electronics, and new energy vehicles, becoming a key material driving industrial technological advancement.

The aerospace sector imposes extremely stringent requirements for lightweight materials with high-temperature resistance, radiation resistance, and structural stability. Leveraging its comprehensive performance advantages, CFRP has become a core material for extreme environments.

Spacecraft Structural Components: CFRP is extensively used in satellite mounts, spacecraft heat shields, and the Long March 9 rocket fairing. Through optimized structural design, it achieves a 40% weight reduction, significantly enhancing launch efficiency. For reusable spacecraft, polyimide-based composites capable of withstanding temperatures above 600oC are being prioritized for development to meet the extreme environmental demands of multiple return flights.

Aviation Engine and Airframe Structures: CFRP is applied in aircraft engine outer ducts, wings, and tail surfaces. Its outstanding thermal stability and mechanical properties withstand high temperatures and vibrations during engine operation while reducing airframe weight and improving fuel efficiency. Mass production of high-modulus carbon fiber has been achieved through dry-jet-spinning technology, supporting the domestic production of structural materials for large aircraft.

Defense Equipment Applications: In next-generation ballistic missiles, hypersonic vehicles, and other defense equipment, CFRP can be used for manufacturing warhead casings, engine nozzles, and control surfaces. It not only meets structural weight reduction requirements but also withstands high-temperature ablation during high-speed flight, ensuring the operational performance of the equipment.

As electronic devices evolve toward miniaturization, flexibility, and higher frequencies, carbon fiber-reinforced polyimide composites—with their low dielectric loss, high-temperature resistance, and flexible properties—serve as a key enabler for miniaturization and flexibility, establishing themselves as a core material in the electronics and information technology sector.

Semiconductor Packaging and Integrated Circuits: In 5G chip and millimeter-wave antenna packaging, CFRP serves as an interlayer dielectric material for buffer layers, passivation layers, and redistribution processes. Its low dielectric constant reduces high-frequency signal transmission losses. Enhanced with low-temperature curing technology, its curing temperature can be lowered from 350oCto 200oC, further adapting to advanced packaging requirements.

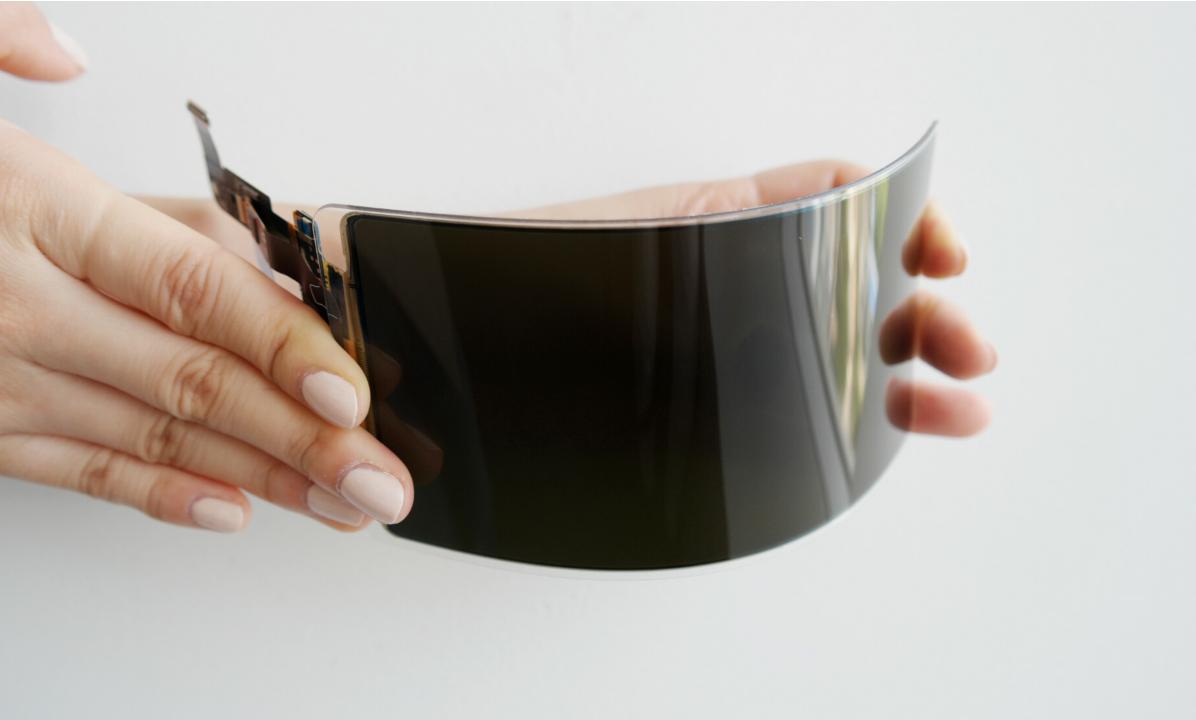

Flexible Electronics and Display Technology: As a core component in flexible AMOLED display substrates and cover layers, ultra-thin polyimide carbon fiber composites (with thicknesses as low as 5 μm) support the bend resistance and high-resolution design of flexible screens. Within flexible circuit boards, their excellent high-temperature resistance and dimensional stability ensure the long-term reliable operation of microelectronic devices.

Electromagnetic Shielding and Thermal Management: Graphene modification of carbon fiber-reinforced polyimide composites significantly enhances their electrical and thermal conductivity, enabling their use as electromagnetic shielding materials and high-efficiency heat dissipation components. This addresses electromagnetic interference and heat dissipation challenges in electronic devices.

Amidst the new energy vehicle industry’s drive for technological advancement and lightweighting, carbon fiber-reinforced polyimide composites have emerged as a critical material for enhancing vehicle performance and safety, providing dual assurance for both weight reduction and structural integrity.

Power Battery Systems: CFRP is utilized in battery separators, insulating films, and high-density wiring components for battery management systems. Its high-temperature resistance (long-term operating temperature up to 300oC) and flame retardancy effectively enhance battery system safety while reducing failure risks. Compared to traditional wiring harnesses, polyimide-based FPC wiring offers greater compactness, meeting the space optimization demands of new energy vehicles.

Automotive Structures and Powertrain Components: CFRP is extensively used in body frames, chassis, and engine mounts. It reduces vehicle weight by over 25% while significantly enhancing structural strength and impact resistance, thereby improving fuel efficiency and driving range. Its low friction coefficient and self-lubricating properties also make it suitable for robotic joints and automotive transmission gears, minimizing wear and reducing energy consumption.

In-Vehicle Electronics Protection: Within automotive displays and semiconductor packaging, CFRP withstands complex driving conditions like vibration and humid heat, extending electronic component lifespan and ensuring stable operation of onboard systems.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.