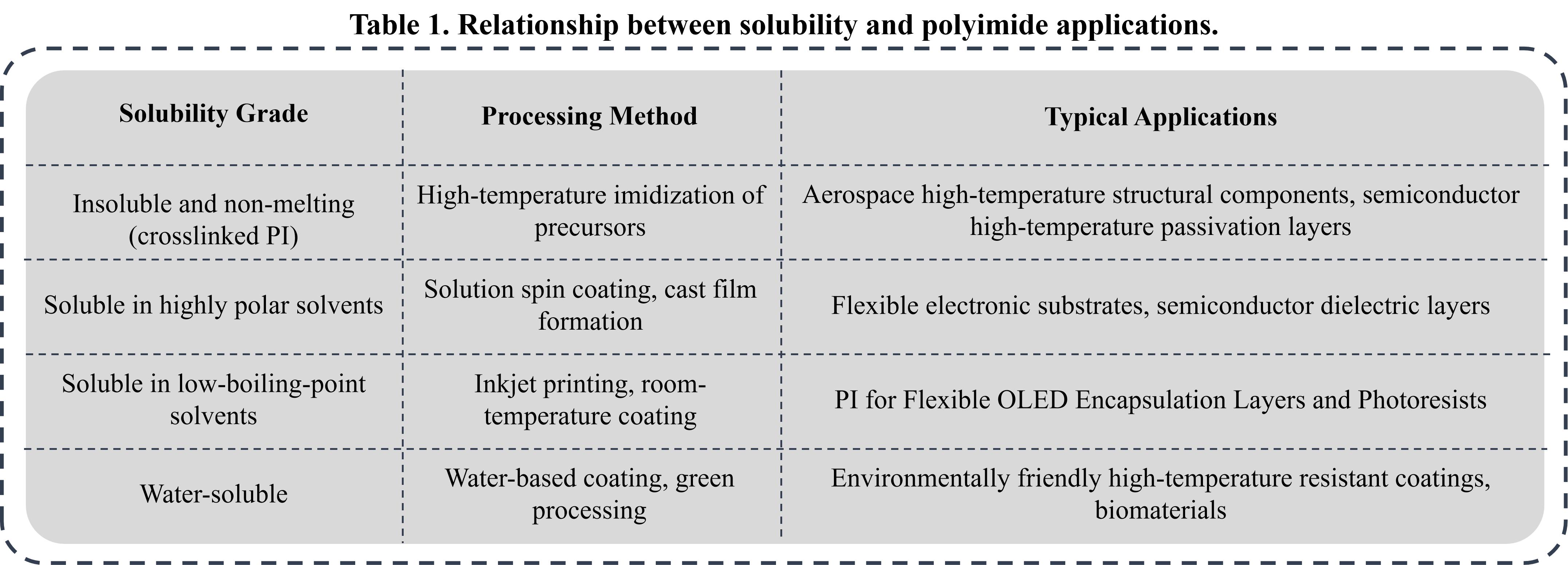

The solubility of polyimide (PI) is one of the core bottlenecks in its processing and application. The polyimide molecular chain contains a large number of rigid aromatic ring structures, and strong hydrogen bonding and π-π stacking interactions exist between molecules. This results in unmodified pure PI being virtually insoluble in organic solvents and difficult to process by melting. Traditional processing relies on the polyamic acid (PAA) precursor method, which involves synthesizing soluble PAA, coating it to form a film, and then undergoing high-temperature imidization at 200~400oC to dehydrate and form PI. This process is energy-intensive, time-consuming, and prone to substrate deformation and coating cracking at high temperatures, limiting its application on thermosensitive materials such as flexible substrates and plastic bases.

The solubility of PI is directly related to the chemical structure of its molecular chains. By adjusting the molecular structure through chemical or physical means, solubility can be enhanced while preserving PI’s core properties. The primary modification methods for improving polyimide solubility are listed below:

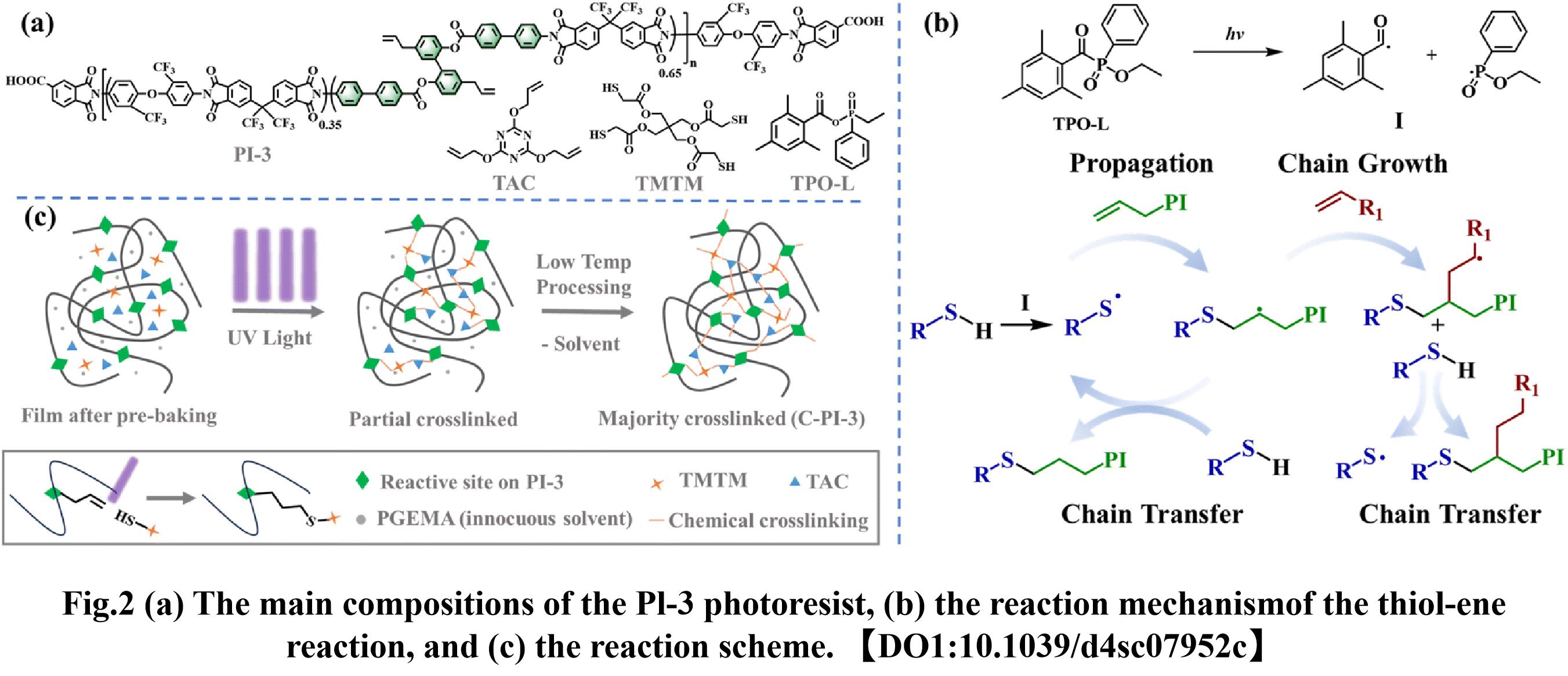

Chemical Modification: This involves optimizing the molecular structure at the fundamental level, representing the primary approach to enhancing PI solubility. Introducing flexible groups, such as ether bonds, ester bonds, or aliphatic segments—increases molecular chain flexibility, thereby improving solubility; Incorporating bulky side groups or substituents, such as monomers containing trifluoromethyl, phenyl, or tert-butyl groups. The steric hindrance of these groups disrupts π-π stacking interactions, significantly improving solubility. For example, trifluoromethyl-containing PIs are soluble in low-boiling-point solvents like acetone and tetrahydrofuran; Synthesizing copolymeric PIs by copolymerizing rigid monomers with flexible/substituted monomers to balance solubility and high-temperature resistance; Employing dianhydride or diamine monomers with asymmetric structures to reduce crystallinity and enhance solubility; Prepare soluble precursors such as polyimide salts or esterified polyimides, which dissolve in water or common organic solvents and convert to high-performance PIs after low-temperature processing.

Physical Modification: Enhance overall solubility through blending with other materials, leveraging compatibility for applications requiring moderate performance. Blend PI with highly soluble polymer resins (e.g., epoxy resins, polyphenylene oxides) to achieve solubility in specific solvents via compatibility, enabling production of adhesives, coatings, etc. Adding small-molecule plasticizers (e.g., phthalates) weakens intermolecular forces in PI, improving its dispersion in solvents, though this may reduce the material's high-temperature resistance and mechanical properties.

The modified soluble PI compositions can be directly dissolved in low-toxicity or environmentally friendly solvents like NMP or DMAc to form high-solids, low-viscosity coatings, adhesives, or resin solutions. This enables room-temperature or low-temperature processes such as coating, casting, and inkjet printing. This approach eliminates the high-temperature imidization step, reducing energy consumption and equipment requirements while improving coating uniformity and minimizing defects like pinholes and bubbles. Consequently, it significantly lowers the cost of large-scale production.

In core applications such as semiconductor packaging and flexible electronics, solubility is a prerequisite for PI to function effectively. In wafer-level packaging (WLP) and flip-chip packaging, PI commonly serves as a passivation layer, buffer layer, or dielectric layer. Enhanced solubility enables PI solutions to form uniformly thick films (with precision control at the micron or even nanometer level) via spin coating or spray coating, meeting the high-precision demands of semiconductor devices. Simultaneously, the soluble system is compatible with photolithography processes. Unexposed areas can be dissolved using developer solutions to achieve patterned fabrication, replacing traditional etching processes and simplifying workflows. Flexible OLED substrates and flexible printed circuits (FPC) demand exceptional flexibility and processability from their substrates. Soluble PI compositions enable ultra-thin flexible PI films via solution casting or direct inkjet printing for flexible circuit insulation layers—eliminating high-temperature processing and preventing thermal damage to flexible substrates, thereby advancing lightweight and portable flexible electronics.

Traditional PI processing relies on highly toxic solvents like NMP and generates significant emissions during high-temperature processes. Enhanced solubility enables the development of PI systems based on low-toxicity/environmentally friendly solvents (e.g., cyclohexanone, methyl propylene glycol acetate), reducing VOC emissions. Concurrently, the development of water-soluble PI formulations enables water-based processing, completely eliminating the use of organic solvents and meeting global environmental regulations for greener electronic materials.

Enhancing the solubility of polyimide compositions is pivotal for transforming PI from a “difficult-to-process high-performance material” into one with “refined, green applications”. This addresses the core need to balance its outstanding properties with practical processing feasibility, impacting production efficiency and cost control. PI plays an irreplaceable role, particularly in semiconductor packaging and flexible electronics.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.