The Bottom Anti-Reflection Coating (BARC) is an essential supporting material in deep ultraviolet (DUV) and extreme ultraviolet (EUV) lithography processes. Applied between the photoresist and the wafer substrate, its core function is to suppress interference from substrate reflection during photoresist exposure, thereby ensuring the resolution and uniformity of fine patterns.

In traditional photolithography processes without BARC, when exposure light passes through the photoresist to reach the wafer substrate (such as silicon wafers, metal layers, or dielectric layers), it undergoes specular or diffuse reflection. This reflected light re-enters the photoresist, causing two core issues. First, the standing wave effect occurs when incident and reflected light interfere within the photoresist film, creating periodic light intensity distributions. This results in “rippled” sidewalls after photoresist development, compromising pattern size uniformity. Second is the reflectivity dependency effect: significant differences in reflectivity among substrate materials (e.g., Si, SiO2, Cu) cause inconsistent actual exposure doses across different regions of the same wafer surface. This induces local pattern distortion and line width deviation. BARC fundamentally resolves these issues through dual mechanisms of optical interference cancellation and light absorption, serving as the “precision assurance layer” for advanced lithography processes.

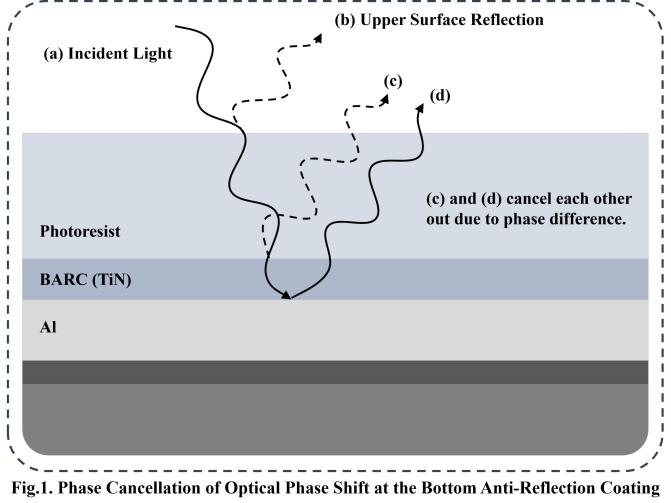

BARC’s mechanism of action encompasses both interference cancellation and light absorption types, with practical applications often utilizing composite materials combining both. The interference cancellation mechanism operates on the principle of optical thin-film interference. By precisely controlling the thickness and refractive index of the BARC, it ensures that the reflected light from the upper surface and the lower surface exhibit a 180o phase difference and nearly equal amplitude. When these two reflected light beams overlap, they cancel each other out, thereby reducing the intensity of reflected light within the photoresist film. The light-absorption mechanism introduces chromophores—such as anthracene, naphthalene, or benzocyclobutene derivatives—into the BARC molecular structure. These chromophores exhibit high molar absorptivity at photoresist exposure wavelengths, efficiently absorbing light penetrating the photoresist. This reduces the light intensity reaching the substrate, thereby minimizing reflected light generation at its source.

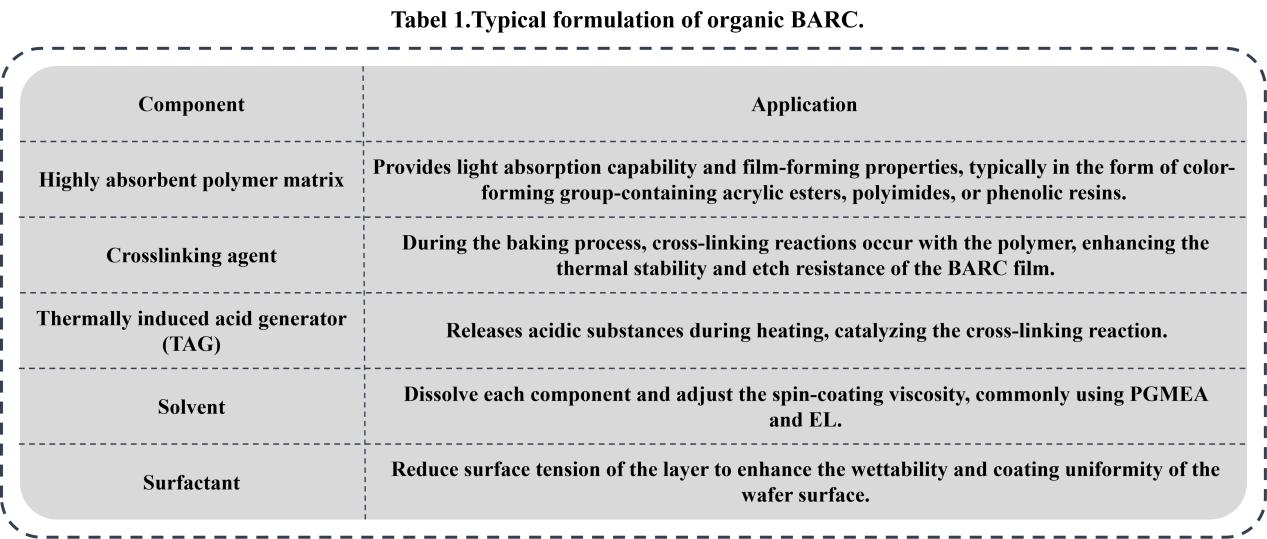

In modern lithography processes, inorganic BARCs (e.g., SiON, TiN) have been progressively replaced by organic spin-on BARCs (SOBC) due to the challenges in thickness control and poor compatibility with photoresists. A typical formulation for organic BARC is shown in the table below.

As semiconductor process nodes advance to 7 nm and below, BARC’s optical matching, thermal stability, and process compatibility have become critical factors limiting lithography precision. Currently, BARC still faces several technical challenges in practical applications.

BARC Compatibility Challenges for EUV Lithography

The extremely short EUV wavelength (13.5 nm) significantly increases material absorption coefficients. The high light absorption of traditional BARCs leads to substantially increased photoresist exposure doses, reducing lithography efficiency. Simultaneously, EUV photoresist films are extremely thin, demanding stricter thickness uniformity for BARCs. Solutions include molecular design to reduce chromophore content, developing low-absorption EUV-specific BARCs, optimizing refractive index matching, or employing atomic layer deposition (ALD) to fabricate inorganic/organic composite BARCs for improved thickness uniformity.

Collapse Risk in High Aspect Ratio Patterns

In 7 nm and below processes, lithography patterns exceed an aspect ratio of 5:1. Post-development, interfacial stress between BARC and photoresist can cause pattern collapse. Solutions include reducing in-film stress by adjusting polymer crosslink density to develop low-stress BARCs, or introducing hydrophilic groups to improve developer penetration uniformity and reduce surface tension on patterns after development.

Challenges of Narrowing Process Windows

As lithography process windows continue to shrink in advanced nodes, fluctuations in BARC optical parameters directly cause process window closure. Solutions include online optical monitoring to track BARC thickness and refractive index in real time, or developing adaptive BARC materials that dynamically adjust optical properties based on substrate reflectivity.

Future developments include synthesizing multifunctional integrated BARCs that combine anti-reflection, planarization, and anti-contamination properties within a single material to streamline lithography workflows. Atomic Layer Deposition (ALD) BARC processes, enabling atomic-level film thickness control, represent a key direction for ultra-fine BARC development and are currently being trialed in select advanced processes. Developing eco-friendly BARCs, such as water-soluble BARC systems, reduces organic solvent usage and lowers environmental costs in lithography processes. These and numerous other research priorities will gradually transition into practical production applications, driving significant advancement in the photoresist industry’s cutting-edge processes.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.