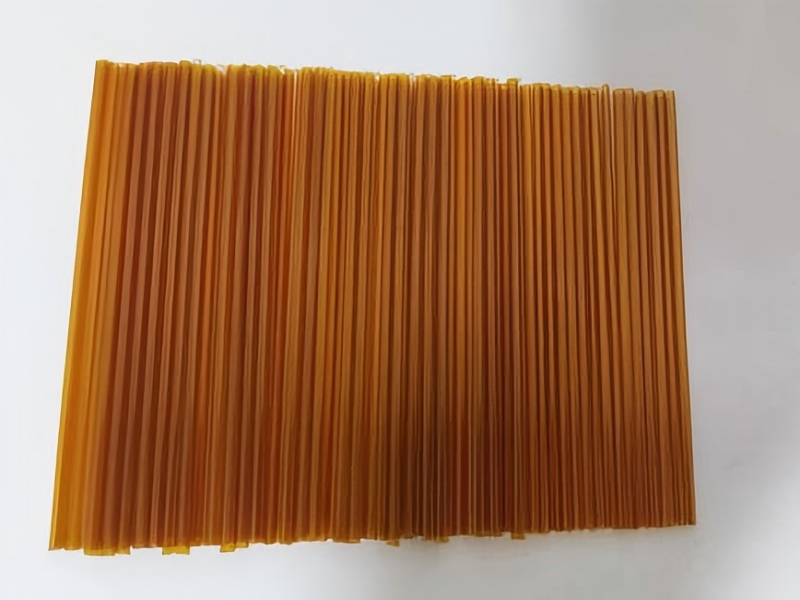

Polyimide tubes are high-performance tubes made of polyimide resin processed by precision craftsmanship, which contain imide-based chain links in their molecular structure and belong to aromatic heterocyclic polymer compounds. These materials are widely used in engineering fields in extreme environments with high temperature resistance, chemical resistance, high strength and excellent electrical insulation as their core characteristics.

Item | Acceptance requirements | Unit |

Color | Brownish yellow | / |

Rockwell hardness | 45-65 | HRE |

Notch impact strength | ≥100 | Kj/m2 |

Tensile strength | ≥100 | MPa |

Elongation at break | ≥8.0 | % |

Bending strength | ≥100 | MPa |

Modulus of elasticity | ≥2600 | MPa |

Density | 1.41 | g/cm3 |

Water absorption | 0.16 | % |

Surface resistivity | >1012 | Ω/sq |

Extreme environmental adaptability

High temperature resistance: long-term working temperature up to 280 ℃, instantaneous resistance of 400 ℃, far more than ordinary plastics.

Low temperature resistance: remain flexible and not brittle under -269℃ (liquid nitrogen environment).

Chemical Stability

Resistant to strong acid, alkali and organic solvent corrosion, suitable for chemical and pharmaceutical industries and other harsh environments.

Excellent mechanical properties

Tensile strength up to 170-400MPa, flexural modulus up to 20GPa (glass fiber reinforced), both high strength and light weight.

Electrical insulation and dielectric properties

Low dielectric constant, low dielectric loss, suitable for high frequency circuits, electromagnetic shielding and other precision electronic scenes.

Biocompatibility

Non-toxic and compatible with human tissues, meets the standards of medical-grade materials, and can be in direct contact with biological fluids.

Processing and Design Flexibility

It can be molded by injection, molding, laser cutting, etc. It supports customized design and meets the needs of complex structures.

Aerospace field

High-temperature components: used in engine fuel systems, thermal protection structures and spacecraft components, such as heat shields and seals.

Lightweight structures: replacing traditional metal materials to reduce the weight of the vehicle and improve fuel efficiency.

Electronics and Microelectronics Industry

Insulating materials: used as circuit board substrate, chip package layer and dielectric layer of flexible display, to ensure the stable operation of electronic equipment.

High-temperature connectors: Used for electrical connections in high-temperature environments (e.g., above 300°C) to prevent current leakage.

Chemical and energy field

Corrosion-resistant piping: conveying strong acid, alkali and other corrosive media, suitable for reaction kettles, high-temperature reaction vessels and other scenarios.

Battery and solar module: as lithium battery diaphragm, solar cell base plate, to enhance the durability of energy equipment.

Medical devices

Biocompatible components: Manufacturing artificial blood vessels, catheters and implantable medical devices to meet the needs of sterility and high temperature sterilization resistance.

Automotive & Machinery Industry

Wear-resistant components: used in engine seals, piston rings, bearings, etc. to withstand high temperature and pressure environments.

Polyimide tubes and parts with its “high temperature, corrosion resistance, high strength” three core advantages, has become a key material in aerospace, electronics, medical and other high-end fields. With the progress of technology, its application potential in new energy, flexible electronics and other emerging areas will be further released.