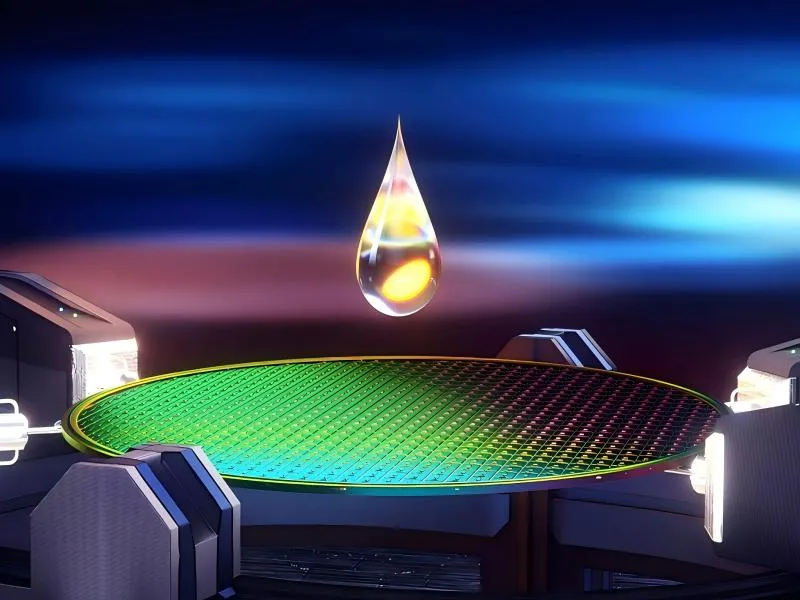

Heynova's PAG products have ultra-high purity and excellent photosensitizing properties. Through self-developed molecular design technology, the company has realized precise control of acid diffusion while ensuring extremely low metal impurity content, especially suitable for advanced processes below 28nm. The company's products have wide compatibility and flexible customization, and can work with a variety of resin systems, compatible with mainstream photoresist systems, effectively improving the resolution and pattern fidelity of photoresist.

Heynova's photoacid generator (PAG) in the semiconductor applications show a variety of advantages:

High quality: The product has extremely high purity and low impurity content, which effectively avoids the introduction of impurities in the photolithography process and ensures the high precision and reliability of semiconductor manufacturing.

High yield: High quantum yield of photoacid generator, a small amount of light can generate a sufficient amount of acid, significantly improve the efficiency of lithography, shorten the exposure time.

Good compatibility: Good compatibility with all kinds of photoresist resin, it can effectively avoid phase separation and other quality problems, to ensure the accuracy of photolithography pattern.

Good thermal stability: Can meet the high temperature requirements of complex lithography processes.

Customizable design: The molecular structure of PAG can be adjusted according to the production process, which is suitable for special processes.

As a key photosensitive material for photoresists, PAG plays a central role in semiconductor manufacturing. In KrF photoresist, after exposure at 248nm wavelength, sulfonic acid is generated to induce structural changes in the resin and precisely regulate pattern transfer with a resolution of 120nm, which is suitable for chip manufacturing in mature processes. ArF photoresist is used with 193nm light source, and PAG meets the requirements of high-resolution and low roughness for advanced processes up to and including 7nm, and the accuracy of line width is controlled at ±3nm with the help of high acid productivity and strong acidity. Meanwhile, in the lithography of TFT arrays for display panels, the PAG helps the photoresist to form fine circuits and improve the display performance of the panels.