The company's photoinitiator product line is extremely rich and complete, covering both mainstream and specialized fields, which can meet the diversified procurement needs of downstream customers. With strong R&D strength, we are constantly launching new products such as those suitable for UV-LED curing. Process innovation leads to efficient production and ensures stable supply. Our core products use innovative processes to improve quality, reduce costs and minimize pollution. In addition, we can customize our products according to customers' needs and optimize the ratio of products in different applications to help customers reduce costs and increase efficiency.

The company's photoinitiator products have the following core advantages:

Full category coverage: The company provides a complete product line including free radical, cationic, macromolecule and water-based photoinitiators, which can fully meet the differentiated needs of different application scenarios such as UV coatings, inks, adhesives, 3D printing, and so on.

Scale and cost advantages: The company has a number of modernized production bases, through upstream and downstream resource integration, with significant scale effect and cost competitiveness.

Promote continuous technological innovation: The company has established cooperation with a number of corporate research centers, universities and scientific research institutes to promote cooperation laboratories in the field of UV-LED curing and other cutting-edge technologies continue to innovate.

Excellent quality assurance: Our products have passed ISO9001, ISO14001 and other international management system certifications, and have won the trust of customers around the world for their high purity and stable performance.

The company's photoinitiators adopt advanced synthesis process and refining technology, which simplifies the production process, reduces the consumption of raw materials and process hazards, reduces the emission of three wastes, improves the production efficiency and stability of the products, and realizes the continuous and automatic control of the production.

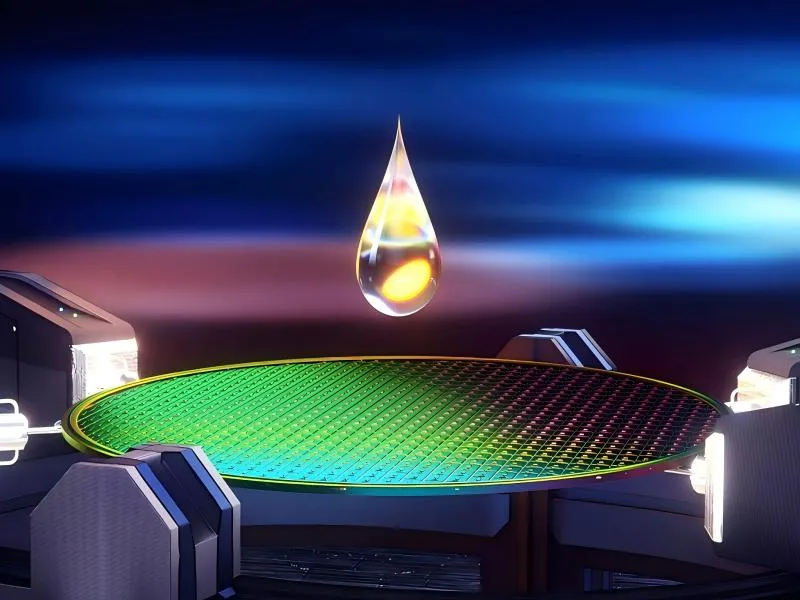

The products are widely used in many fields: providing fast curing solutions in UV coatings for wood, automotive and industrial coatings; ensuring high-precision pattern curing in printing inks for packaging printing and electronic products; achieving solvent-free bonding in the field of adhesives, which is especially suitable for the assembly of medical devices and electronic components; and serving as a key ingredient in the photosensitive resins for 3D printing to guarantee molding precision.

In addition, our special photoinitiators are also used in PCB electronic inks, fiber optic coatings and other high-end fields, continuing to promote the innovation of light-curing technology.