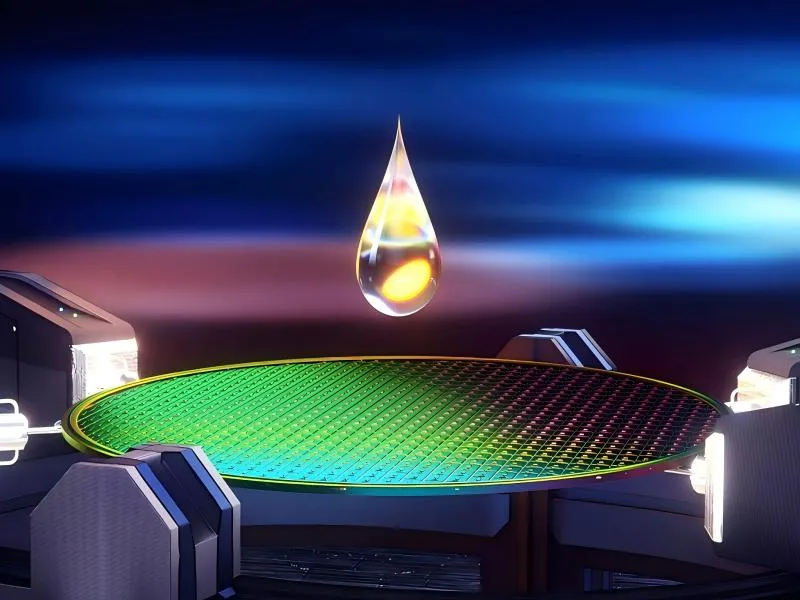

The company's photoresist additive products are mainly used to optimize photoresist performance. Firstly, their high purity and low impurity content ensure that no contamination is introduced during the photolithography process, guaranteeing high precision and reliability in semiconductor manufacturing. Secondly, to enhance the adhesion of photoresist, the unique additives can make the photoresist and the wafer close to each other, and will not come off after etching, ion implantation and other subsequent processes, so as to effectively guarantee the quality of photolithography. In addition, the company provides customized services to optimize the overall performance of the photoresist by adjusting the additive formula according to different lithography processes and specific customer needs.

Photoresist additives optimize the comprehensive performance of photoresist by precisely regulating the synergistic effect of each component, such as:

Alkali and photodecomposable alkali: Improve the development speed and development uniformity, reduce the defects in the development process.

Homogenizer and surfactant: Improve the flatness and uniformity of the photoresist, reduce bubbles and particles in the coating process.

Antioxidants and stabilizers: Extend the shelf life of photoresist, improve the stability and reliability of photoresist.

Pigments and dispersants: Improve the visual effect and ease of operation of the photoresist.

Curing agent: Enhance the adhesion and etching resistance of photoresist, improve the stability of photoresist in the subsequent process.

Photoresist additives are widely used in the lithography process in semiconductor manufacturing. Through the rational selection and use of photoresist additives, the performance of photoresist can be significantly improved to provide customized solutions for different applications.

In semiconductor manufacturing, additives are used to optimize the performance of photoresist, improve resolution, contrast and sensitivity, and meet the needs of high-end lithography processes such as KrF and ArF. For display panel manufacturing, additives are used to enhance the photoresist's light-sensitive performance and pattern transfer quality to ensure the fine manufacturing of display panels. In the field of PCB manufacturing, the additive improves the photoresist's light-sensitive speed and pattern accuracy, ensuring the high quality production of circuit boards.