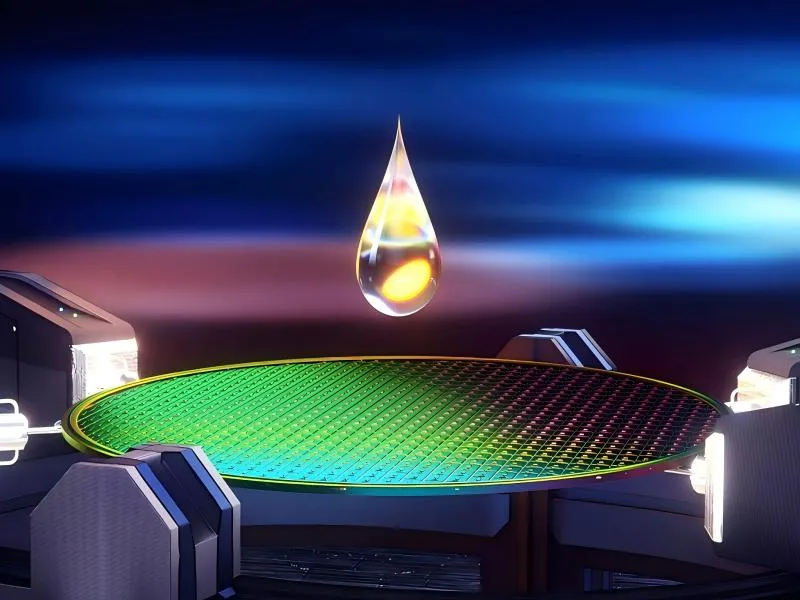

Photoresist resin is the core material in the semiconductor lithography process, and its performance directly affects the precision and yield of chip manufacturing. At present, the photoresist resin provided by the company can achieve nanometer impurity control, and the metal impurity content of the electronic grade resin can be stably controlled at ppb level, avoiding wafer contamination and guaranteeing the yield of advanced process below 28nm. In addition, we can provide precise customization of molecular structure and support the adjustment of molecular weight and distribution on demand, with low molecular weight resins to improve resolution and high molecular weight to enhance etch resistance.

Our photoresist resin products have the following core competitive advantages in the semiconductor manufacturing field:

Cutting-edge technical performance: Adaptable to EUV/ArF/KrF lithography processes, supporting advanced processes of 7nm and below, with line width uniformity (CDU) controlled within ±1.2nm.

Excellent process compatibility: Wide exposure dose window, excellent etch resistance, compatible with mainstream developing and etching processes. Excellent material properties

Excellent material properties: High purity grade, optimized rheological properties, excellent thermal stability.

Customized services: Specialty modified resins are available to support customer collaborative development and provide process integration solutions.

The company's photoresist resin is the key component of photoresist, used in different types of photoresist, with a wide range of applications covering high-tech industries such as semiconductor manufacturing, display panel manufacturing and PCB manufacturing, meeting the needs of chip processes from micron to nanometer scale.

In semiconductor manufacturing, it is suitable for 28nm-7nm advanced process, G line/I line photoresist resin is used for memory chips, and KrF/ArF photoresist resin supports the mass production of logic chips. In display panel manufacturing, photoresist resins are used in LCD and OLED panel manufacturing, especially in the production of color filters and black matrices. In PCB manufacturing, photoresist resin is used as a matrix material to determine key properties such as adhesion and corrosion resistance of the adhesive film.