Photoresist solvents are key components in photoresist formulations, primarily serving to dissolve solid constituents such as resins, photoinitiators, and additives into a uniform, stable liquid photoresist. They also evaporate during coating and baking processes to form the film. The type, purity, and volatility characteristics of these solvents directly impact the photoresist's solubility, coating uniformity, film thickness control, and lithographic performance.

Photoresist solvents are predominantly high-purity organic solvents requiring electronic-grade (EL/UP-grade) specifications, with metal ion impurities ≤1 ppb and stringent control over particulate contaminants. Based on chemical structure and application scenarios, they are primarily categorized as follows:

Ester solvents (most widely used, core solvents for mainstream positive photoresists)

Ester solvents offer excellent solubility, adjustable evaporation rates, and good compatibility with photoresist core resins like phenolic resins and poly(p-hydroxystyrene) (PHS). They form the core solvent systems for G-line, I-line, KrF, and ArF photoresists.

Propylene glycol methyl ether acetate (PGMEA): The most versatile photoresist solvent, combining moderate evaporation rates, low toxicity, and high solubility. Suitable for G-line/I-line photoresists, it also serves as the primary or blended solvent component for KrF photoresists, ranking among the most extensively used solvents in semiconductor photoresists.

Butyl Acetate (nBA): Features a relatively fast evaporation rate, primarily used in PCB photoresists and low-end display photoresists. It can also function as a blending solvent to regulate overall evaporation speed and enhance coating leveling properties.

Ether and Ether-Alcohol-Ester Solvents

Propylene Glycol Methyl Ether (PGME): Often blended with PGMEA to regulate the evaporation gradient of mixed solvents, improving photoresist wetting on silicon wafers/glass substrates and reducing film thickness non-uniformity. Primarily used in mixed solvent systems for I-line and KrF photoresists.

Ethylene glycol monoethyl ether acetate (CAC): Possesses extremely strong solvency. Historically used in certain negative photoresists and specialty resists. Due to its high toxicity, it has been progressively replaced by PGMEA and is now employed only in limited specialized applications.

Ketone Solvents

Ketone solvents exhibit strong solvency but often demonstrate poor compatibility with photoresist resins and volatile stability. They are primarily used as auxiliary solvents and rarely serve as primary solvents:

Cyclohexanone: Dissolves PI photoresists and certain negative photoresists. Suitable for PCB and flexible display photoresist systems. Also functions as a dissolution aid for high-solids-content photoresists.

Acetone, Methyl Ethyl Ketone (MEK): Extremely fast evaporation rates limit their use to photoresist dilution, cleaning, or temporary solvents. They cannot be incorporated into final photoresist formulations due to risks of coating defects and film thickness control issues.

Aromatic Solvents

Xylene, Toluene: Historically used in certain negative photoresists (e.g., cyclized rubber-based negatives). Now largely obsolete due to toxicity concerns, VOC emissions, and poor solubility with advanced photoresist resins. Remain in limited use only in select industrial-grade low-end photoresists.

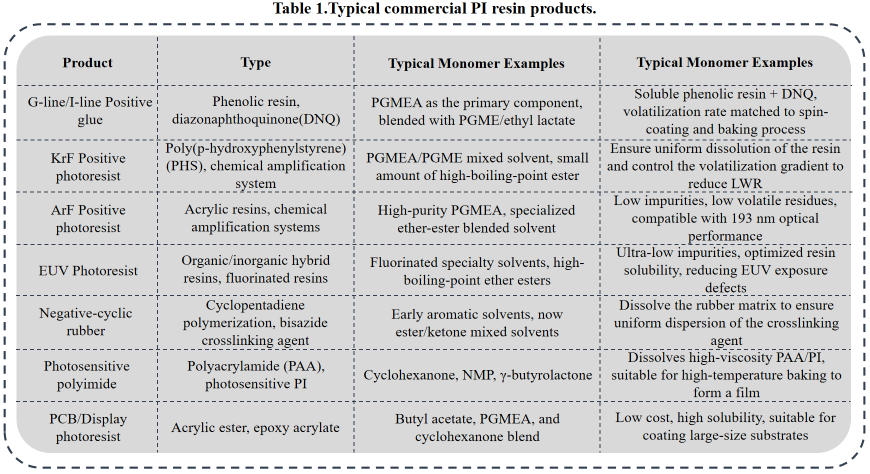

Photoresist solvent selection fundamentally depends on the core resin structure, with significant variations in solvent formulations across different photoresist types:

At present, photoresist solvents are subject to stringent core performance requirements. They must exhibit excellent solubility, fully dissolving the main resin, photoinitiators, and additives without precipitation, separation, or gelation, thereby forming a uniform polymer solution that ensures consistent composition after photoresist film formation. Additionally, photoresist solvents require favorable gradient evaporation characteristics: rapid evaporation of most solvents during spin coating to form an initial film layer; followed by slow residual evaporation during soft baking to prevent bubbles, pinholes, or orange peel within the film; ultimately leaving no solvent residue in the final film. Photoresist solvents must meet high electronic-grade purity standards to avoid interfering with the acid quenching effect in chemically amplified photoresists. Particle content and non-volatile residues (NVR) must be strictly controlled to prevent particle defects in the photoresist film. Resist solvents must exhibit excellent wettability with substrates to ensure uniform film thickness during spin-coating/slit-coating processes. They must not react adversely with the resist's photoinitiator system or developer, thereby not affecting exposure, development, or etching processes. Additionally, they must balance safety and environmental characteristics, achieving low toxicity and low VOC emissions to comply with semiconductor industry environmental standards, while progressively phasing out highly toxic solvents.

This is the first one.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.