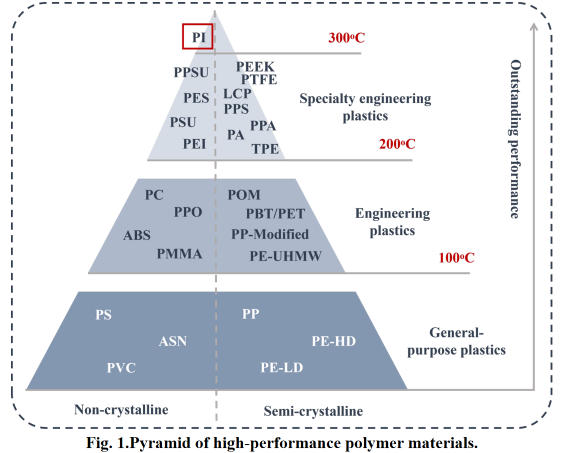

Polyimide resin is a high-performance polymer featuring an imide ring in its main chain. It combines exceptional high-temperature resistance, high mechanical strength, outstanding dielectric properties, and excellent chemical resistance. As a core material in high-end fields such as aerospace and electronics, it is hailed as the “material at the pinnacle of the polymer pyramid”.

The PI backbone features repeating imide rings (-CO-NR-CO-) often combined with rigid/flexible groups such as aromatic rings, ether bonds, or ketone bonds, determining its core properties: rigid aromatic rings and planar imide rings enhance thermal stability (Td5%>500oC) and mechanical strength; Ether bonds, sulfonyl groups, and fluorinated groups reduce dielectric constant (Dk) and improve solubility;

Capping groups (e.g., maleimide, phenylvinyl) determine the curing behavior and processing window of thermosetting PIs.

Classified into two major categories based on processing and crosslinking characteristics, covering all scenarios from general-purpose to aerospace applications:

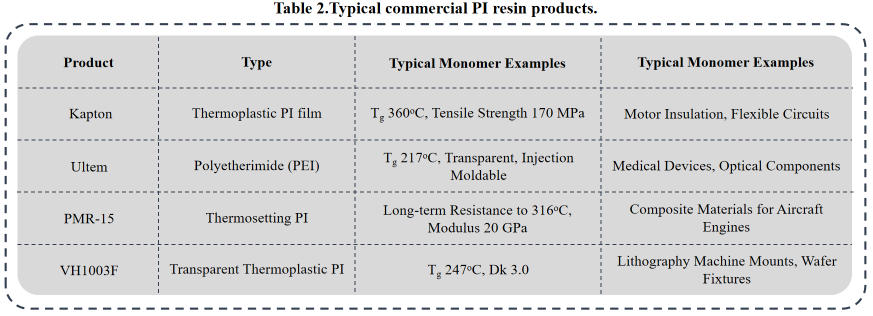

Thermoplastic Polyimide (TPI): Linear or mildly branched polymers with no chemical crosslinking between chains. They soften or melt when heated, solidify upon cooling, and allow repeated processing. Introducing flexible groups (e.g., ether linkages -O-, ketone groups -CO-, aliphatic chains) or bulky side chains disrupt chain regularity, lowering the melting point (Tm) and glass transition temperature (Tg) to impart fluidity. Typical examples include Ultem® (PEI, polyetherimide), LARC-TPI, and Torlon® (PAI, polyamideimide).

Thermosetting Polyimides (TSPI): Contain reactive end groups in the prepolymer (oligomer) that undergo crosslinking reactions under heat/pressure to form a three-dimensional network structure, becoming non-melting and non-soluble after molding. Typical examples include PMR-15, Avimid®, and bis-maleimide (BMI) resins. Classified by structural features:

Norbornene-capped (PMR type): Examples include PMR-15, featuring nadic ester end groups that undergo “reverse Diels-Alder” crosslinking at elevated temperatures.

Phenylacetylene-capped (PEPA): Features phenylacetylene end groups that undergo cyclotrimerization crosslinking at elevated temperatures.

Bis-maleimide (BMI): An addition-curing type that crosslinks via double bond addition.

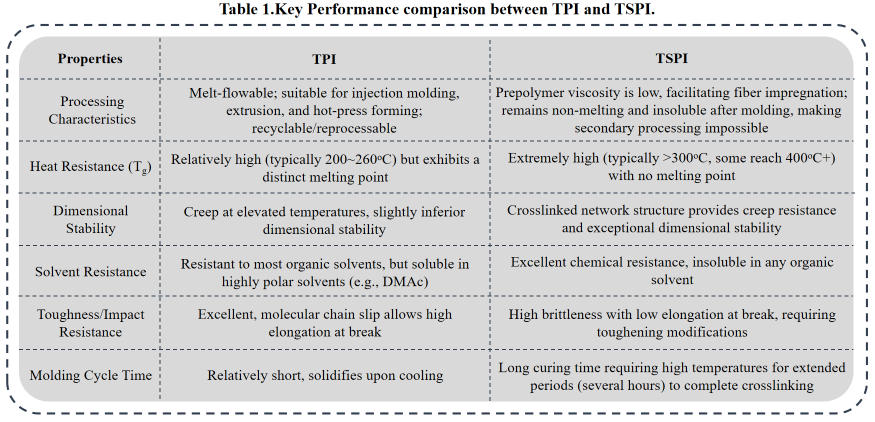

The manufacturing process for TPI resembles that of traditional thermoplastics: injection molding for complex structural components; extrusion for films and sheets; and hot pressing for laminates or composites. TPI offers advantages in high forming efficiency, recyclable waste, and suitability for mass production. However, its high melting temperature (>300oC) demands specialized equipment. TSPI manufacturing processes include prepreg preparation, compression molding/autoclave molding, and RTM (Resin Transfer Molding). TSPI facilitates the production of high-performance fiber-reinforced composites (CFRPI), but its curing process is complex, time-consuming, and non-recyclable once scrapped.

TPI applications include flexible circuit board substrates, connectors, sockets, and chip carriers (requiring high toughness and machinability); heat-resistant structural components around engines in automobiles and aircraft, sensor housings; high-temperature-resistant insulating films, flexible display substrates. In aerospace applications, TSPI primarily serves as primary/secondary load-bearing structural components and can also be used in advanced packaging for high-end microelectronics (e.g., fan-out packaging, power device substrates); it is also used to produce high-temperature-resistant oil-free lubricated bearings and sealing rings.

In summary, TPI is selected when complex structures, rapid prototyping, moderate toughness, recyclability, and long-term operating temperatures below 250oC are required. Conversely, TSPI is typically chosen when pursuing extreme heat resistance (>300oC), solvent resistance, zero creep, and high-strength composites, without concern for molding costs or cycle times. The two materials are not substitutes but complementary: TPI addresses the difficult processing challenges of traditional PI, while TSPI maintains PI's unparalleled performance in extreme environments.

Contact us to learn more about our advanced electronic chemicals and speciality polymer materials, and how they can enhance your production performances.