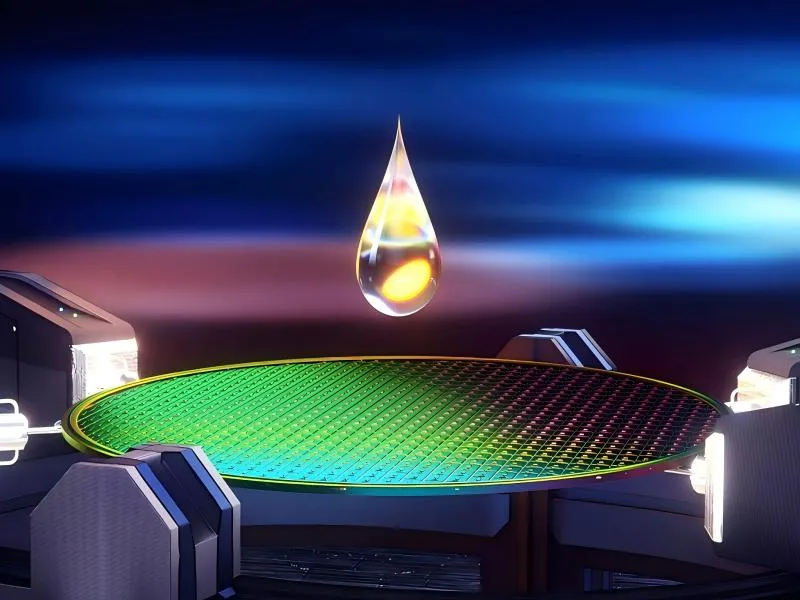

The Company's semiconductor antireflective coating monomer is a key raw material used in the manufacture of bottom anti-reflective coating (BARC). BARC are used in semiconductor manufacturing to eliminate reflected light from the substrate and avoid abnormal exposure of the photoresist, thus improving lithography resolution and pattern transfer accuracy. Its good compatibility with photoresist ensures good adhesion, reduces the risk of pattern collapse, and safeguards lithography quality. In the etching process, it shows a high etching selectivity ratio, protects the photoresist layer and reduces damage to the wafer.

The company's semiconductor anti-reflective coating monomer can significantly improve the photolithography process window and graphics resolution, and has been verified by a number of foundries, has obvious advantages:

High purity process: Adopting distillation purification technology, the purity reaches over 99.9%, which meets the requirements of semiconductor-grade applications;

High process window: Effectively reduces the sensitivity of exposure dose and focal length, and enhances the fault-tolerance of the lithography process;

Strong stability: Excellent thermal and storage stability, providing reliable and stable material support for semiconductor manufacturing;

Customizable design: The molecular structure can be adjusted according to customer needs and customized monomer design.

The Company's anti-reflective coating monomers play an important role in semiconductor manufacturing. BARC made of anti-reflective coating monomer is coated under the photoresist, which mainly reduces the light reflected from the substrate and prevents the reflected light from interfering with the exposure of the photoresist, thus improving lithographic precision and consistency.

In semiconductor manufacturing, BARC is widely used in KrF, ArF and other high-end lithography processes to meet the needs of different processes. In logic chip manufacturing, BARC is used to ensure the lithography accuracy of key structures such as gate and interconnect holes; in memory chip production, BARC is used for lithography of 3D NAND stacked layers and DRAM memory cells to enhance chip integration and performance.