Micron-level printing precision: ±25μm detail reproduction capability (equivalent to 1/3 of the thickness of a hair)

Optical-grade surface: Ra <0.2μm (without post-processing to achieve the surface effect of injection moulded parts)

Nanoscale dispersion technology: filler particle size <100nm, eliminating the effect of the layer pattern

Strength-toughness balance: bending strength of 120MPa + fracture elongation 15% (beyond ordinary engineering plastics) Elongation 15% (beyond ordinary engineering plastics)

Isotropic breakthrough: XYZ direction performance difference <5% (to solve the weakness of traditional 3D printing)

Dynamic performance optimization: notched impact strength up to 15kJ/m² (comparable to glass fibre-reinforced ABS)

High-temperature resistance: 180 ℃ sustained working temperature (aerospace piping test standards)

Bio-compatibility: ISO 10993-5 certified (cytotoxicity certification for direct contact with human body) Cytotoxicity certified (direct human contact possible)

Electrical/thermal conductivity: volume resistivity adjustable range 10³-10⁸Ω·cm (flexible electronic direct hit)

Wide-window curing: support for 385-405nm multi-band light source (compatible with mainstream DLP/LCD devices)

Low shrinkage formula: volume shrinkage <1.5% (reduce deformation cracking)

Fast release: 50% increase in self-peeling (reduce loss of support structure)

Bio-based content: 30% of raw materials from renewable resources (40% reduction in carbon footprint)

Low toxicity and harmlessness: Zero heavy metal additions, compliant with EU REACH standards

Material Utilization: More than 97% of the uncured resin is recyclable

3D printing technology plays an important role in the aerospace field. Through 3D printing technology, lightweight, high-strength parts can be manufactured, reducing the weight of aircraft, satellites and other aerospace vehicles and improving performance.

3D printing technology has enormous potential in the field of medical device manufacturing. It can rapidly and cost-effectively produce medical devices tailored to patient needs, such as prosthetics and dental braces.

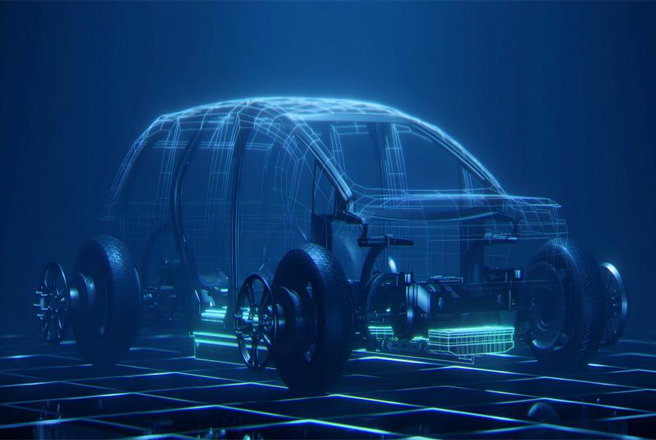

The advent of 3D printing technology has made personalized customization possible. In the automotive industry, 3D printing allows for the rapid production of parts tailored to individual needs, reducing manufacturing costs and shortening production cycles.

The application of 3D printing technology in education is also becoming increasingly widespread. Educators can use 3D printers to create various teaching models to better demonstrate and explain teaching content.

3D printing technology has revolutionized product design. By utilizing this technology in the design process, companies can improve their design processes, reduce costs, and increase testing opportunities and flexibility.

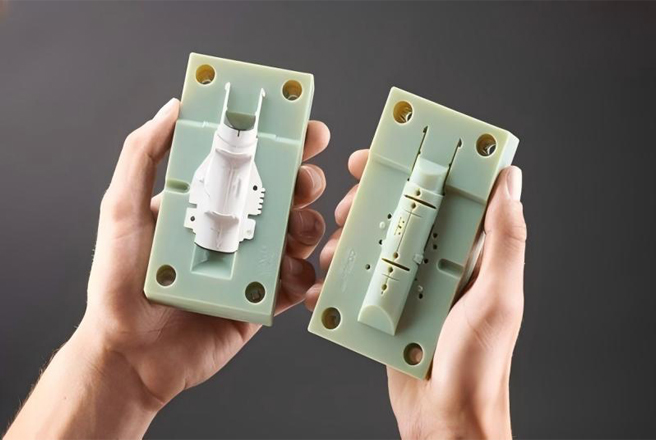

The application of 3D printing technology in mold manufacturing is significant. It can greatly simplify the production process, reduce costs, increase production efficiency, and offer more innovative and personalized designs.