Photoresist monomer is the basic unit of photoresist, determines the basic chemical and physical properties of the photoresist. Acrylate monomers, polymerisation reaction can form a polymer skeleton with good corrosion resistance and resolution, to give the photoresist hardness, adhesion and other properties, to ensure that the photoresist in the photolithography process to achieve precise pattern transfer.

Photoresist additives in the photoresist system is crucial, it is to improve the quality of the key elements of the photoresist, can optimise a variety of photoresist properties. Plasticisers can enhance the flexibility of photoresist, to prevent rupture in the photolithography process. Surfactants can improve the coating performance, so that the photoresist is more evenly distributed on the substrate. Stabilizers can enhance the stability of storage and extend the service life.

Photoacid generator (PAG) in the photoresist system has a key role, is the photolithography process triggered by chemical changes in the key substances. When exposed, the photogenic acid generator absorbs photons to produce acid, the acid will catalyse the reaction of the polymer in the photoresist, such as changing the solubility of the photoresist, and then achieve the pattern transfer.

Photoinitiators are key components in the photoresist system, which can trigger the polymerisation reaction of the photoresist, and are the key initiating factor for the curing of the photoresist in the photolithography process.

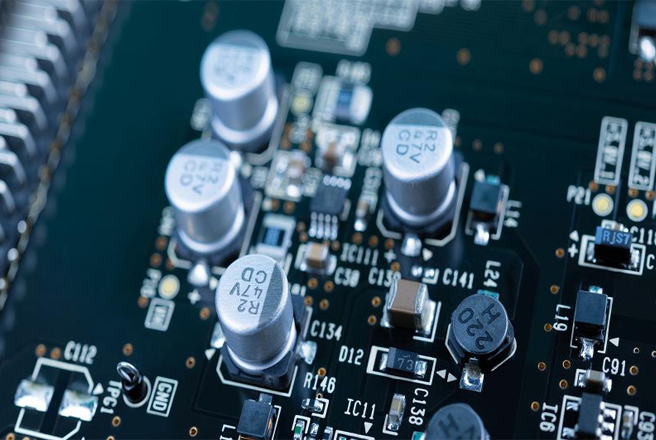

Photoresists play a vital role in the semiconductor industry and are one of the basic materials used in the manufacture of high-performance electronic devices, mainly for logic chips and memories.

Wafer Level Packaging (WLP) technology is an important technological innovation in the field of integrated circuit packaging. Photoresists play a critical role in this process. One of the core steps in WLP technology is the formation of fine conductive paths and connections on the wafer surface through photo-lithography.

Photoresists are not only an essential material in the manufacture of display panels, they directly affect many important properties of LCD panels, determining the size and pitch of the pixel dots on the display panel, thereby enhancing resolution.

In MEMS processing, lithography is widely used to fabricate various micro-structures such as micro-sensors, micro-actuators, and microcircuits. Through photo-lithography, the designed pattern can be accurately transferred to the substrate, providing a precise template for subsequent processes such as etching and deposition.

Photoresists play a key role in the manufacture of optical devices, such as optical waveguide devices in optical fibre communications. In addition, photoresists are used to manufacture microelectronic devices such as sensors and display devices.

Photoresist is being upgraded from a traditional ‘graphics transfer medium’ to a fundamental material for enabling next-generation information technology, and its application boundaries continue to expand. Research is pending in the direction of quantum computing, photogenic chips, bio-electronics and so on.